Sublimation Ink Are Not Ordinary Printing Inks

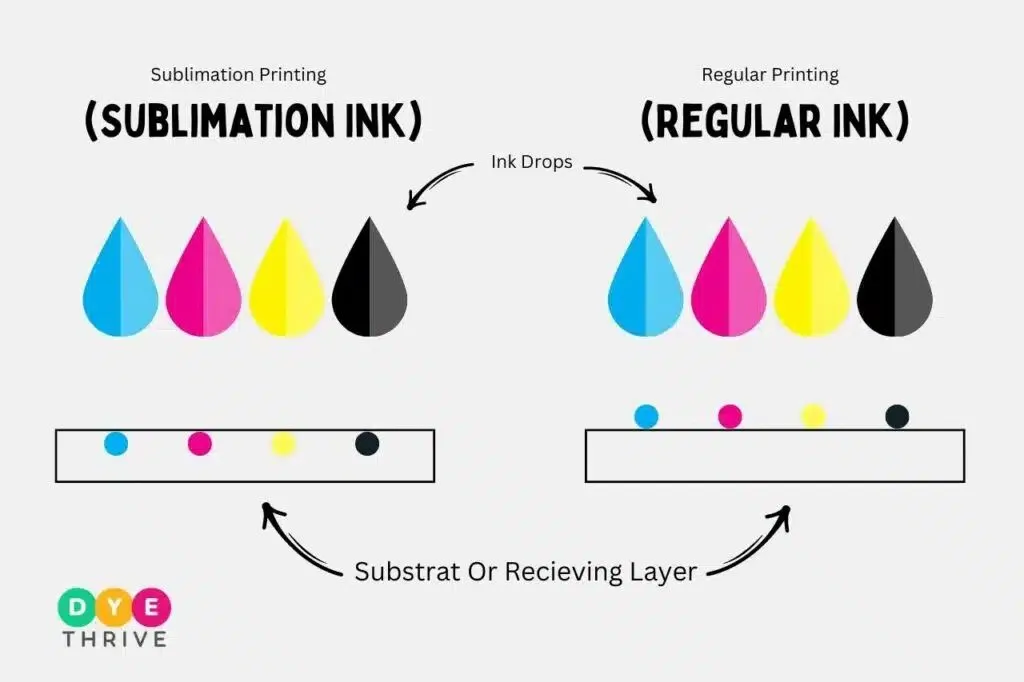

The fundamental difference is that sublimation inks are made to accommodate the reaction of sublimation to heat. Normal printing inks do not have a similar need, so the two are not the same.

The reason why dye-sublimation ink can achieve the property of sublimation when exposed to heat is because of its more specific composition. It is important to be clear here that sublimation inks produced by different manufacturers may not be consistent in their formulations. This is why ink itself varies.

The fundamental difference means that sublimation ink is not to be mixed with regular printing ink. Many people have the bad habit of mixing inks, thinking that the printer can handle it all. Doing so can actually damage the printer and cause more damage.

While the object of the example in the figure is a regular ink, so, in fact, is the DTF ink. See also: Is DTF Ink And Sublimation Ink The Same?

Sublimation Ink Should Be Used On Specific Papers

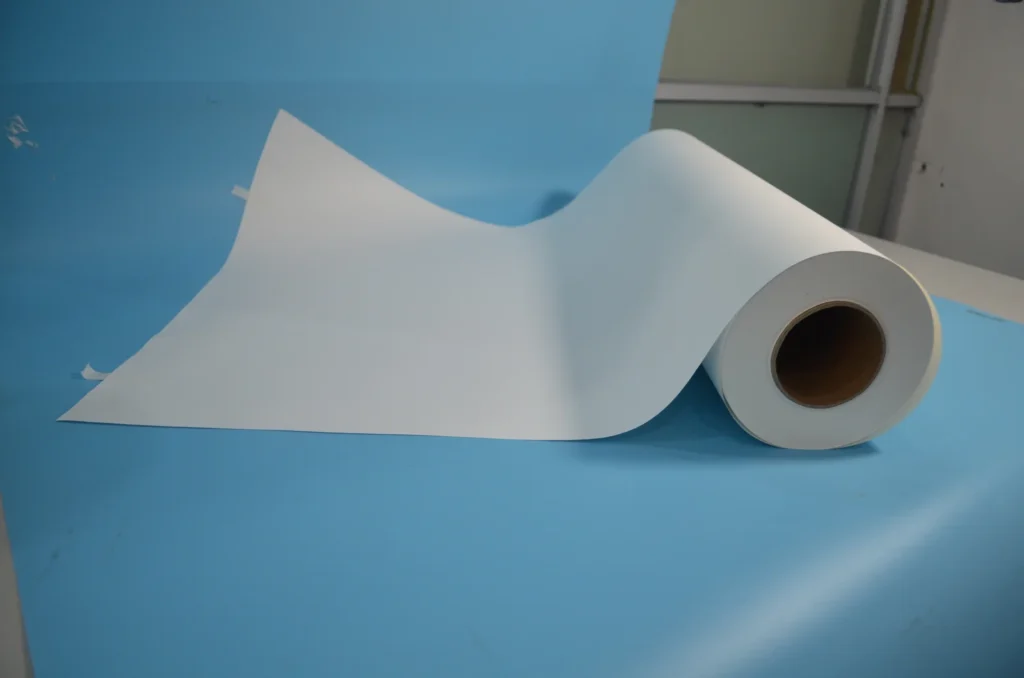

Sublimation inks can only be used on sublimation and heat transfer paper, but not on any other type of paper! The reason for this is that sublimation ink needs to be absorbed by the paper in order for the heat transfer to work. Other types of paper do not have this property, which makes sublimation impossible. Sublimation paper has a special silicone-based coating that temporarily adheres to the sublimation ink.

Ordinary paper will only allow you to attach the ink to the paper, preventing the transfer. Secondly, the transfer operation is required to withstand high temperatures, and ordinary paper does not have that either. You can understand that sublimation paper (or heat transfer paper) is uniformly paired with ink, and they both have properties that similar products do not have.

Ink and paper are designed to work together and cannot be used with any regular paper. In other words, sublimation ink cannot be used with regular paper, and sublimation paper cannot be used with regular ink.

Sublimation Inks Can Be Brand-Specific Or Compatible

Brand-specific sublimation ink refers to ink that is the same model as the printer brand, and this type of ink can generally only be applied to printers of the same brand. Compatible ink, on the other hand, means that as long as the printer printhead is suitable, then it can be used on the printer.

Generally speaking there is no difference between good and bad between brand-specific ink and compatible ink, because the needs and demands are different. However, the compatible ink will be cheaper than the brand-specific type. If the sublimation printer that you have purchased requires the use of its brand-specific ink. Then it is better that you do not bother trying to use compatible ink.

Whether or not you can use compatible ink depends specifically on the printer and has little to do with the ink. Whether there is a gap between brand-specific and compatible needs to be determined by the results you get from your printouts.

Generally speaking, brand-specific ink with the corresponding brand of sublimation printer will be more advantageous. This advantage stems from production debugging and matching, which is repeatedly verified by the same manufacturer during the production process.

Sublimation Ink Also Comes In A Variety Of Colors

Sublimation ink is not just the standard CMYK four colors, you can purchase other colors as well. There are usually light cyan (LC), light purple (LM).

However, it is important to note that sublimation inks in non-standard colors are more compatible with advanced sublimation printers. If your sublimation printer is not too high-end, then it is recommended that you ask the printer manufacturer to make sure.

Some printers use six or eight colors of ink, while industrial-grade sublimation printers may use more. Printers use additional ink colors to improve the final print and increase quality.

This can be important for industrial-grade sublimation printers because they may be used for products such as oil paintings or carpeting. These products usually require higher print quality.

This Ink Has An Expiration Date And Requires Specific Storage Conditions

No matter what kind of ink it is, there is the concept of shelf life, usually one year. Ink sealed in a bottle is stored for a long time, and many people will think that it can still be used in a sealed state. But in fact, as long as the shelf life is exceeded, it can not be used.

Ink is a chemical substance, and such substances are bound to be changed by external factors. This is why ink requires specific storage conditions. In particular, temperature and humidity are two conditions that can affect the shelf life of ink if one of them is not met.

Many people would think that sublimation ink needs to be sublimated to realize the printing, so they think it can withstand high temperature storage conditions. But the fact is that sublimation is a short process, while storage is a long-term process. The problem of deterioration is not formed in a day or two.

When sublimation ink exceeds its shelf life, these things usually happen: print color changes, clogging of the printer nozzles. Sublimation inks that have not been used for too long may result in dull colors, loss of coverage, or impaired print quality.

Dye-Sublimation Ink Has Matching Scenario Applications

This is especially true for large and small wide format printing. If you are a small sublimation printer, the difference in ink capacity can help you plan your production schedule. If you are a high-end large format sublimation printer. The corresponding high-temperature dispersion ink can also better match your printing needs.

There are inks that are adapted to temperature requirements and inks that are adapted to permeability requirements. Different inks are suitable for different usage scenarios, solving various needs from small area printing to large area printing.

Sublimation paper has the concept of grammage, and the size of the grammage matches the corresponding ink. For example, low-temperature sublimation ink is matched with sublimation paper of low grammage. Thus, it seems that paper changes in use with ink.