UV DTF Consumables Information

An Introduction To UV DTF Supplies

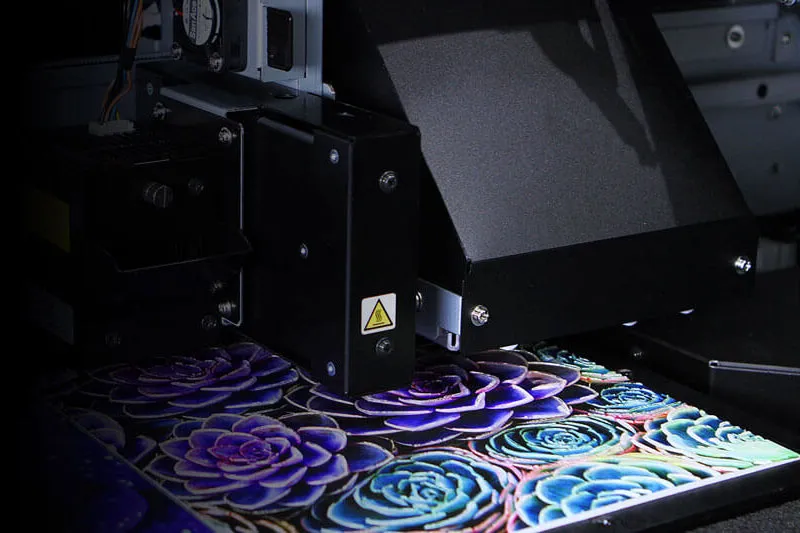

UV DTF consumables consist of two parts: ink and AB films. There is ink specifically designed for curing, hence the alternative name “UV curing ink.” The AB film is a thin film with A and B membranes; in the printing process, the A membrane is used to print patterns, and after lamination, the B membrane is used for the transfer.

At this stage, there is a printing process called “Crystal Labeling Process“, which is essentially a UV DTF printing process, and the products we sell are also for it.

Products made using the crystal label process are called UV DTF stickers. See also: What Is UV DTF Stickers?

Crystal labels can be produced and affixed to most printed matter for quick customization of patterns. The size of the label is determined by the requirements of the printed material. This efficient method saves production time compared to traditional UV printing, which prints and cures directly on the printed material. If the substrate is relatively large, then printing can be quite time consuming.

The Key Differences from UV Consumables

Unlike conventional types of UV printing supplies, processes involving DTF (Direct to Film) have some variations in operation.

Early UV printing had relatively high cost consumption, hence the emergence of UV DTF printing, a process designed to reduce costs to meet market demands.

The biggest difference between them lies in the specific requirements for the film. The advent of AB films has arguably revolutionized the convenience of operations within the industry. This has also indirectly allowed UV printing machinery to access a wider market.

Although they share ultraviolet-curing properties, UV DTF consumables differ from ordinary UV consumables in their specific formulation and application. They are optimized for film-based transfer, making them indispensable for high-quality designs on various surfaces.

The Advantages Of UV DTF Consumables

The versatility of printing substrate

UV DTF printing has the versatility to print on a wide range of substrates. Which is an advantage unparalleled by DTF or Sublimation printing. The success of UV DTF consumables is largely dependent on the quality of the AB film used, making it a crucial element in the process. As long as the AB film can adhere to a surface, printing is possible. But a smooth and even surface is required for optimal results.

The pattern is long-lasting and durable

UV DTF supplies offer a durability after transferring the pattern that no other printing process or supplies can offer.

Normal DTF printing is needless to say, and some would argue that the durability of dye-sublimation printing is no worse than that of UV DTF printing.

However, the fact is that the products after dye sublimation printing are not as good as UV DTF printed products in terms of water washing resistance (both are the same product).

The Drawbacks Of UV DTF Consumables

Not as widely applicable as UV printing

UV DTF consumables can only be used on substrates where film transfer is possible, which is a limitation. Compared to conventional UV printing, the requirements for the substrate surface are also relatively high. If you are printing on a substrate that has a complex surface, then UV DTF printing is not for you.

Complicated process operation

Ink usage in UV DTF supplies is relatively simple as it is usually printed on A films and then cured by light. However, operating with AB films is much more complex. It is essential to ensure the printing room is as clean as possible before printing. Load the AB film onto the roller, making sure the transfer film is aligned correctly. After printing, the A and B films are “married” and then trimmed and weeded as required before being transferred onto the substrate.

In terms of complexity in the printing process, DTF and sublimation cannot compare to UV DTF printing.

Application Of UV DTF Consumables

Judging by the substrate

UV DTF consumables are likely needed if you’re printing on materials such as leather, glass, metal, plastic, acrylic, wood, or ceramic. However, it’s crucial to remember that because the transfer uses a film, the material surface should be smooth for optimal results.

For use with UV DTF printers

UV printers and UV DTF printers are different; UV DTF consumables must be used with UV DTF printers. Just because both printers use UV light curing, you can’t assume that the ink on the supplies is universal. In practice, UV curing inks require different temperatures for the substrate and for the film. The temperature required for curing to the film is more even, which is also good for the maintenance of the printer.

Conclusion

Do not think that UV DTF consumables are equivalent to UV consumables, the difference in their operating process directly determines the difference in the consumables themselves.

You can’t think that UV DTF printing is a panacea, it also has its own limitations, whether to buy this kind of consumables depends on your actual printing needs.