Why are we so against you doing this? In this article, I’ll explain the reasons and some usability tips.

Why You Shouldn’t Mix DTF Ink From Different Brands

DTF ink formulas are not standardized across brands. Each manufacturer designs their ink with unique chemical compositions tailored to specific printheads, film types, and curing conditions. When you mix inks from different sources, you’re essentially creating a chemical experiment with unpredictable results.

For example, in the use of DTF film, there is a phenomenon called “ink flow”, which makes the ink flow like water and does not ink the film correctly. This phenomenon is caused by the use of different inks. In particular, different colored inks and different white inks are used together. If you want to know specifically what causes this phenomenon, you can read this article: What is The DTF Film Ink Bleed Problem

Mix DTF Ink and You Risk Print Quality Issues

One of the most immediate consequences of mixing DTF ink brands is inconsistent print quality. Different ink formulas may vary in:

- Pigment concentration

- Viscosity

- Color balance

- Drying time

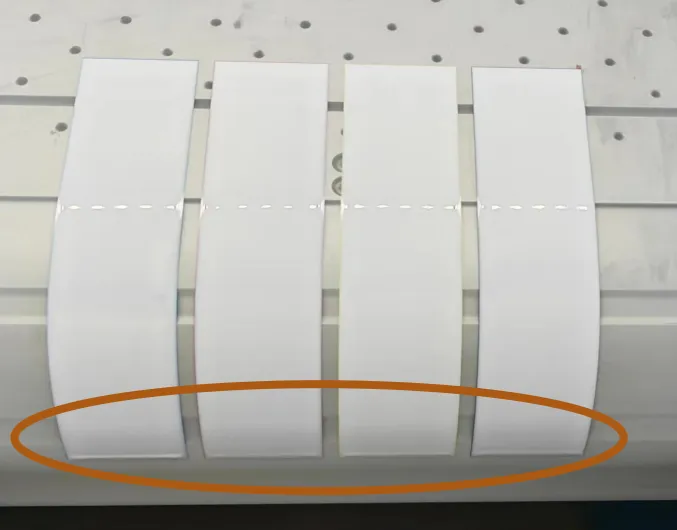

These variations can cause problems like color banding, dull prints, clogged nozzles, or uneven layering—especially when white ink and color inks are not chemically compatible.

Inconsistent color presentation is a common issue. During print testing, if you mix different DTF inks, you might notice that some colors appear normal while others look dull. You might think increasing the ink output can solve this, but that won’t work. DTF printing isn’t just about the ink quality; it also heavily relies on the film and powder. If the ink initially appears dull, it will only worsen during the heating process, potentially leading to missing colors or uneven patches.

It’s important to distinguish here that the “ink starvation” phenomenon of continuous printing with incomplete output may also be the result of mixing different inks. You can read more about it here: What Should I Do If The DTF Ink Breaks During Printing?

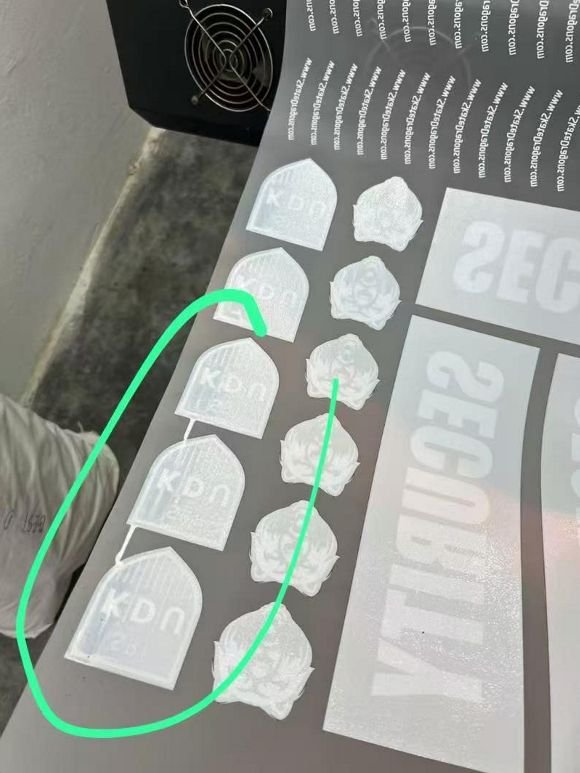

Uneven layering is the main culprit behind ink build-up in DTF films. Since DTF printing involves printing colors first, followed by white, using incompatible inks can prevent the white ink from properly bonding with the colored inks. This leads to the white ink sinking to the bottom and accumulating. See also: What is White Ink Buildup on DTF Film

The mixing of different DTF inks can also make the prints less resistant to cleaning due to the change in chemistry. Maybe you won’t feel this when you just print out, but after one or two washes, you will gradually notice the difference. As in the picture below:

Mix DTF Ink and You May Clog or Damage Your Printhead

The printheads used in different printers may be different. And the ink is adaptable to the printhead. The ink flows more appropriately for that printhead, then the printhead will last longer. When you introduce foreign ink into the system, it may react with residual ink in the lines or printhead. This reaction may cause:

- Gel-like residue or sedimentation

- Printhead clogging

- Nozzle misfiring

- Permanent damage to the ink delivery system

Replacing a damaged printhead can be costly—and often not covered by warranty if incompatible ink is detected. And in DTF printing, changing ink is necessary to take a syringe and pump the ink in the ink path clean, otherwise the mixing of different inks will accelerate the damage of the printhead. This is not worth the cost compared to cleaning the ink path.

Many times, fuzzy streaks in printing are most likely caused by clogged printheads. For more information on the issue of fuzzy bars you can read: How Can I Fix DTF Ink Blurry Streaks When Printing.

Conclusion

In conclusion, the problems caused by mixing DTF inks are far more than what’s listed above, but the points covered in this article should be enough to trouble most people. If you must experiment with changing inks, I suggest you clean your machine thoroughly first, then buy new ink and test it.