We offer Inks, Films, and Powders for this purpose. Contact us for bulk orders.

DTF Printing Supplies Offered by Owcors

DTF printing relies on the interaction of inks, powders and films.

DTF Printer Ink

DTF ink provides vibrant and long-lasting colors, reproduction of the colors, laying the foundation for printing results.

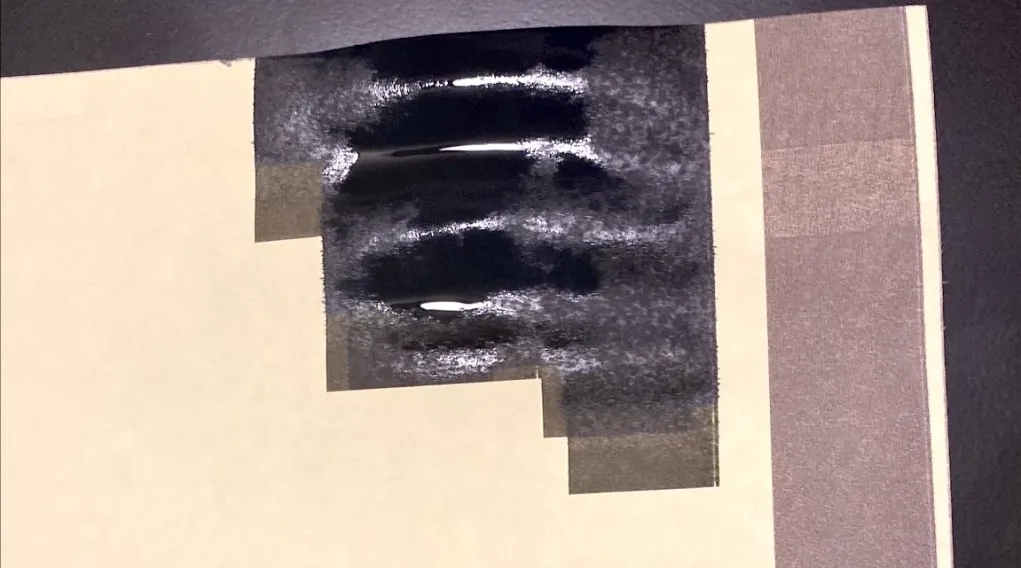

DTF PET Film

DTF film serves as a medium for printing, ensuring high-precision transfer printing that captures details and colors.

DTF Hot Melt Powder

DTF powder provides adhesion, durability, and wash resistance for fabrics, ensuring that the prints stand the test.

Suitable Small Desktop DTF Printer Consumables

Owcors offers printing supplies tailored for desktop DTF printers that are compatible, easy to use and especially suitable for home users, small workshops or start-up brands for trial production or customized business.

suitable medium to large DTF printer Supplies

We also have consumables that demonstrate excellent stability and durability in the face of the intense work of medium and large printing equipment. Suitable for high-speed batch printing and mass production.

Multi-color output, wide color gamut coverage, fine particles, not easy to clog.

High ink absorption, thick coating, anti-scratch and anti-slip, static-free surface.

Multiple types of special powders, strong adhesion, durable and wash-resistant.

Application of DTF Printing Process

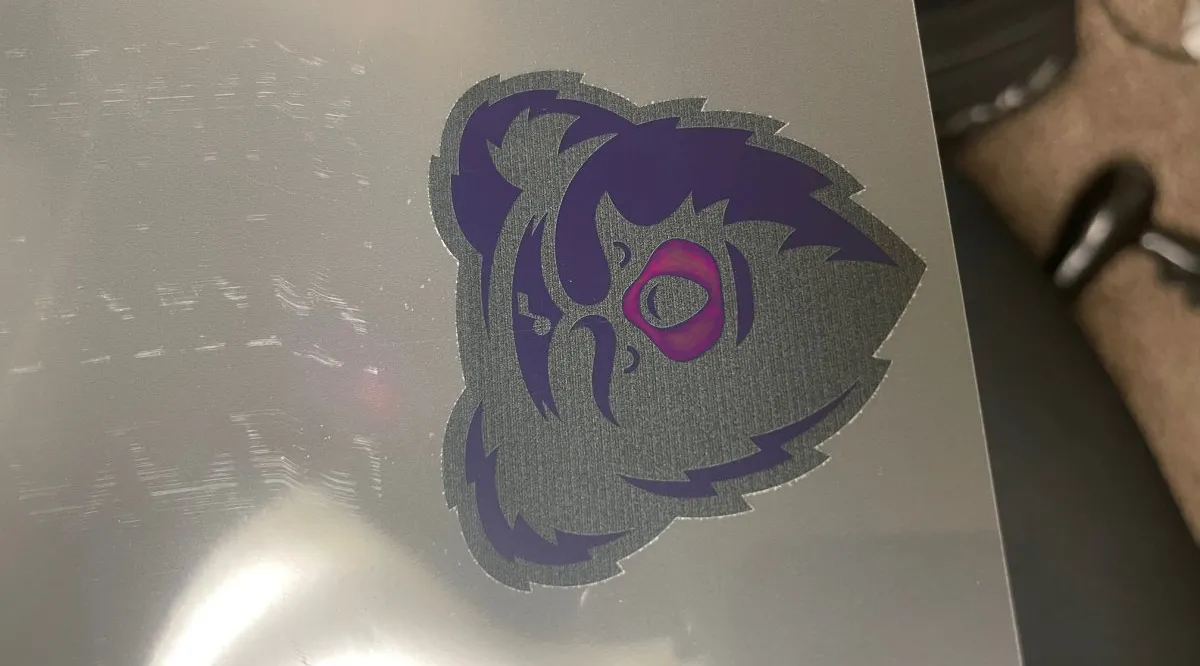

- DTF consumables are the foundation of DTF printing, which produces vibrant, durable designs on specific fabrics and is the production choice for personalized patterned garments such as T-shirts and hoodies.

- DTF printing allows customized graphic transfers on apparel pairings such as scarves and gloves, giving new possibilities to the gift production industry.

- DTF consumables also enable customized shoe upper designs, using the same DTF printing process, adding a vibrant touch to the ever-changing landscape.

- The use of special materials on the surface of the substrate used for the transfer also makes it possible to perform DTF printing on some substrates that cannot be transferred.

Results of Mixing DTF Printing Materials

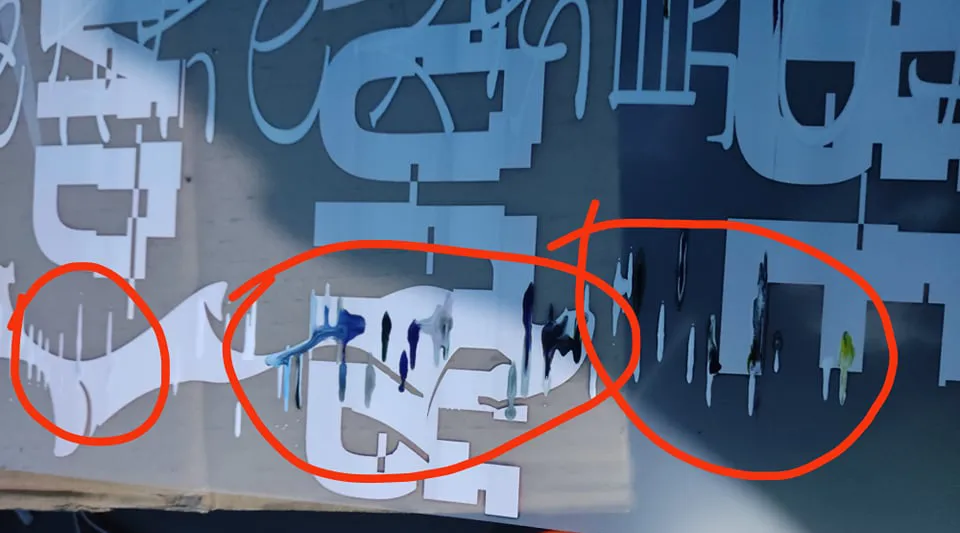

Mixing DTF consumables often leads to clogged printheads, poor bonding, color fading and hardware damage.

Mixing Different DTF Printing Consumables Can Lead To

-

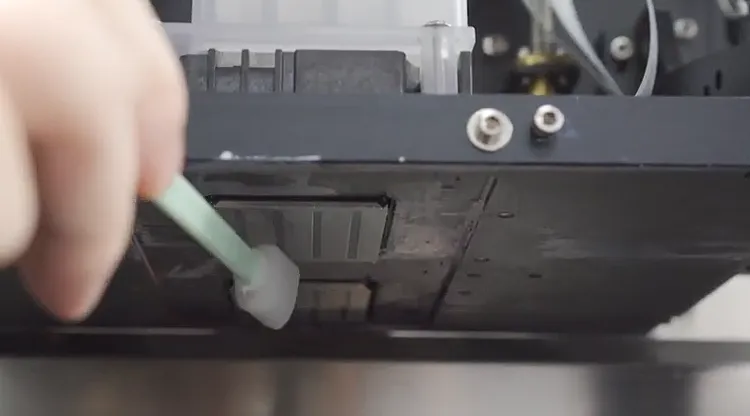

Clogged Printheads

Incompatible inks and powders can cause blockages in the printer nozzles. -

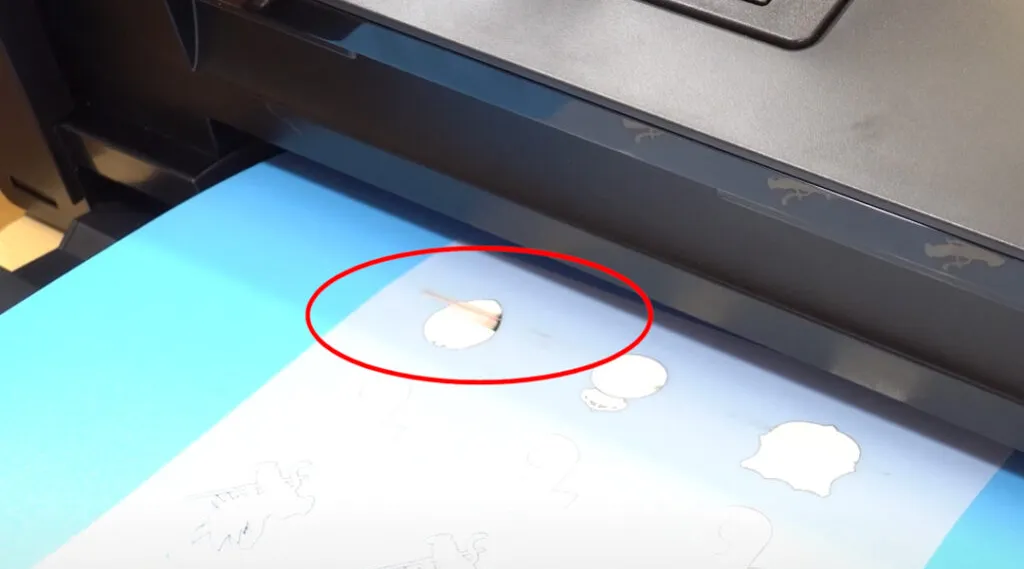

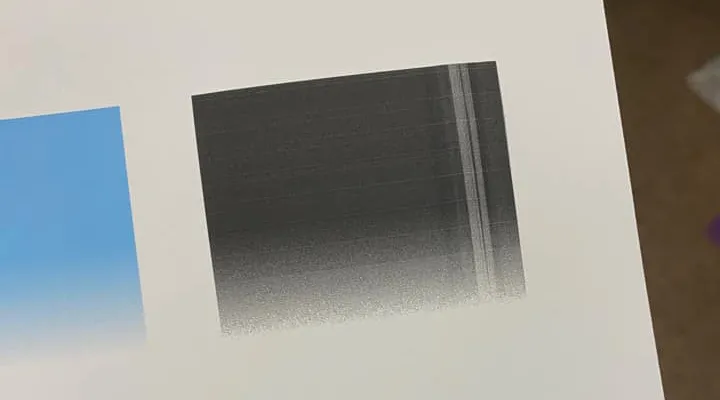

Poor Print Quality

Mixing materials may result in faded colors, streaks, or uneven prints. -

Adhesion Issues

Prints may peel or not adhere properly to the fabric. -

Increased Maintenance

More frequent cleaning is required due to residue build-up. -

Equipment Damage

Incompatible materials can wear out printer components.

Why you should avoid mixing different Consumables

-

Compatibility Concerns

Not all inks, powders, and films are formulated to work together. -

Consistent Results

Using matched materials ensures reliable and high-quality and efficiency printing. -

Efficiency Loss

Mixing can lead to printer downtime and decreased productivity. -

Cost Implications

Wasted materials and potential equipment repairs increase expenses. -

Warranty Voidance

Using unapproved consumables may void printer warranties.

Want to know more? Click here to read the full article on the risks of mixing DTF supplies

What a DTF printing supplies kit can achieve

The table below tests the costs and returns of using the same ink, film, and powder for garment printing on different print heads. You can refer to This Article for more details.

| Printhead | White ink | Color ink | Film | Powder | Baking | Transfer | Printer | Oven | Heat-presser | Daily-output | Return | |

| L1800 | 1.6g | 4.8g | A3+ | 4.2g | 600 Sec | 300 Sec | 30 Sec | $893 | $165 | $110 | $30 | $60 |

| XP600 | 1.7g | 5.1g | A3+ | 4.5g | 230 Sec | 220 Sec | 25 Sec | $1,895 | $247 | $440 | $150 | $300 |

| I3200 | 1.9g | 5.7g | A3+ | 4.8g | 113 Sec | 103 Sec | 20 Sec | $3,850 | $1,170 | $480 | $350 | $700 |

The better the printhead, the more printing you can do while maintaining similar consumable consumption.

Adding just a few milligrams more of consumables makes the difference in yield between different print heads readily apparent.

Assuming a price of $2 per finished print, different print heads show a substantial growth advantage in consumable savings.

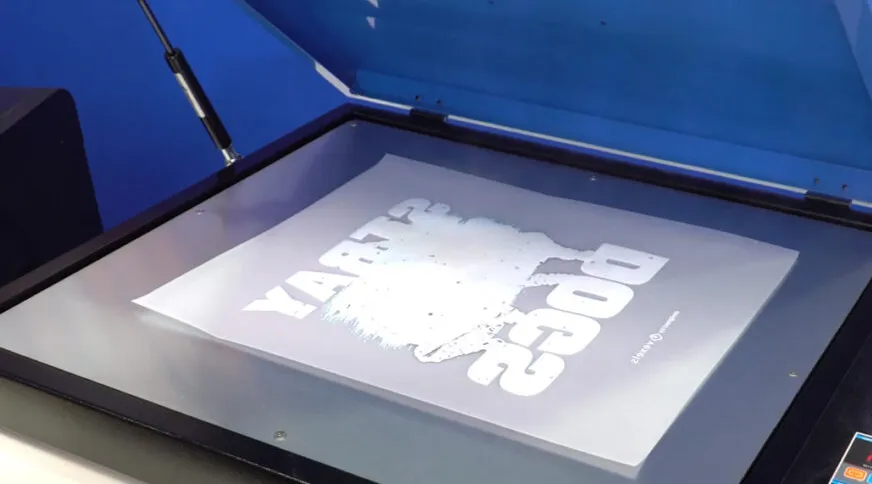

DTF Printing Supplies Workflow

Step 1: Print the image onto DTF Film using DTF Ink, paying attention to print settings and parameters.

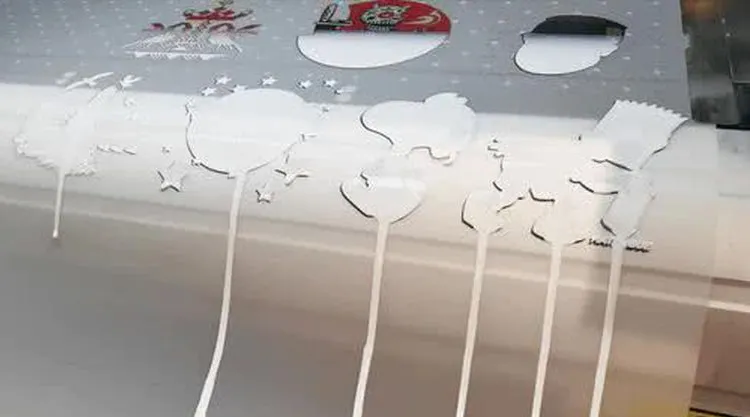

Step 2: Evenly apply DTF Powder over the area covered with white ink, shake off excess powder.

Step 3: Place the film in a dryer or oven and heat to a specified temperature to melt the powder.

Step 4: Position the treated film and fabric in a heat press, and perform the transfer at the recommended temperature and time.

Step 5: After cooling, peel off the film to complete the transfer.