DTF PET Film

Owcors offers three sizes of DTF Film in sheets and rolls that can be customized.

Showing 1–9 of 16 results

-

30CM Chameleon DTF Film

$85.00 -

30CM Colorful Laser DTF Film

$145.00 -

30CM Colorful Reflective DTF Film

$160.00 -

30CM Dazzle Color DTF Film

$70.00 -

30CM Double-Sided DTF PET Film

$34.10Original price was: $34.10.$31.00Current price is: $31.00. -

30CM DTF Diamond Film

$85.00 -

30CM DTF Laser Film

$130.00 -

30CM Glitter Gold DTF Film

$85.00 -

30CM Single-Sided DTF PET Film

$31.90Original price was: $31.90.$29.00Current price is: $29.00.

Owcors DTF Film Features

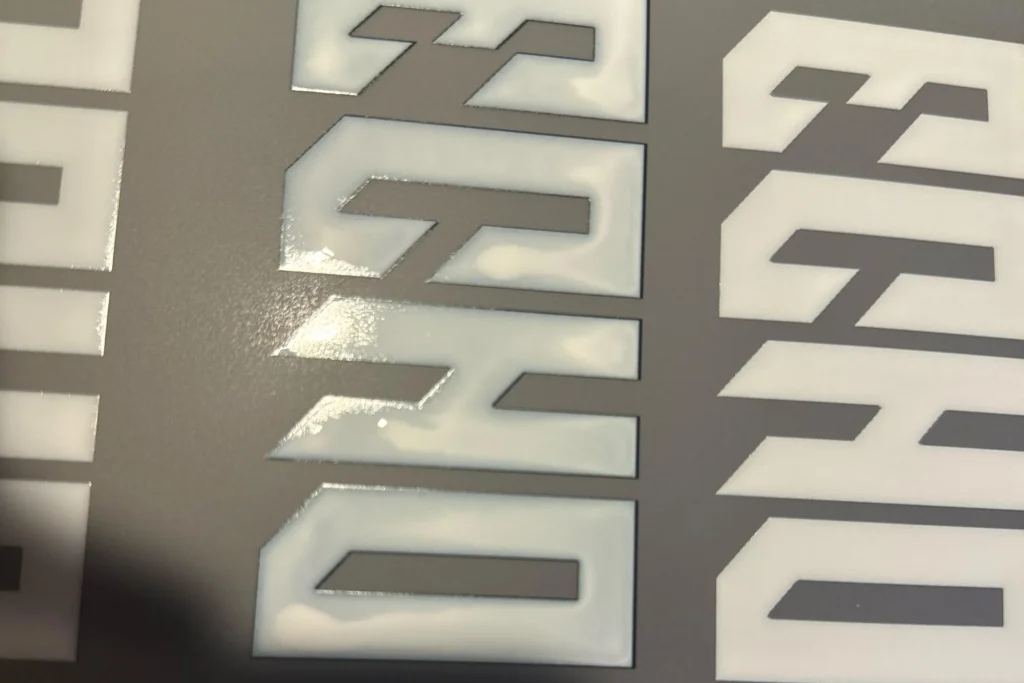

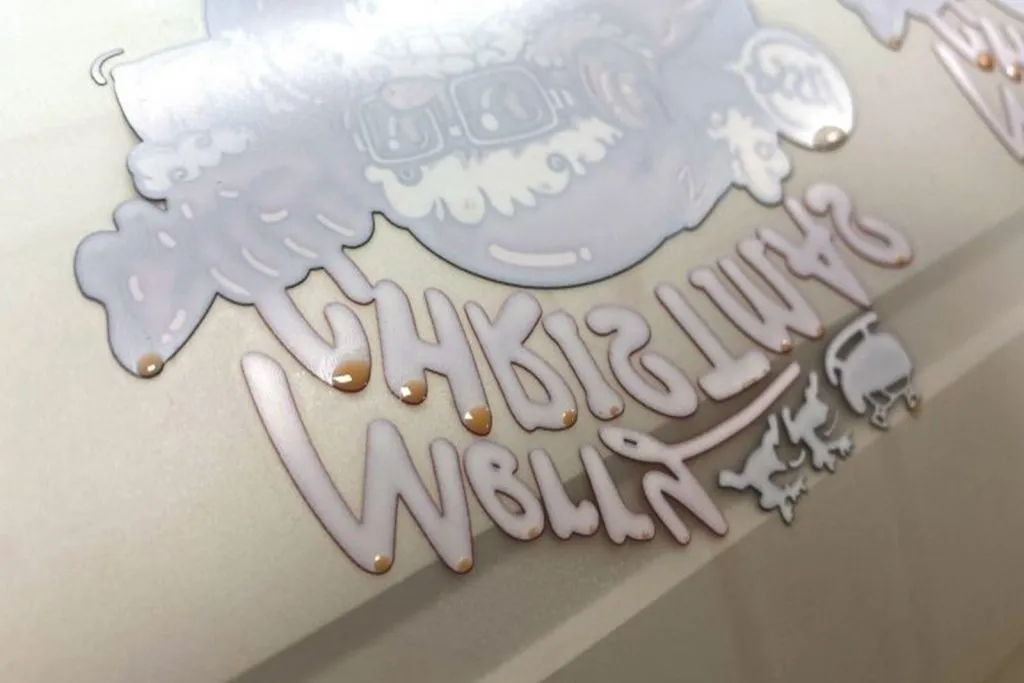

Clean Ink Boundaries

Special coating locks ink in place for sharper, bleed-free prints.

Anti-Curling Stability

Good quality material, not easy to leave marks, no warping or edge curling.

Hot & Cold Peel Options

Supports both hot and cold peel — fast, clean, and flexible.

Multiple Film Selection

Supports customization for various film styles, sheets and rolls form.

Specs & Tech Parameters

| Styles & Models | A3 / A3+ / A4 / 30CM / 33CM / 60CM or Customized |

| Package Specs - Sheets | 50 / 100 / 500 Sheets or Customized |

| Package Specs - Roll | 50M / 100M / 200M or Customized |

| Thickness | 80 μm - 120 μm |

| Film Material | PET (Polyester Film) |

| Peeling Method | Cold Peel / Hot Peel / Seconds Peel |

| Surface Treatment | Matte / Glossy / Other Options |

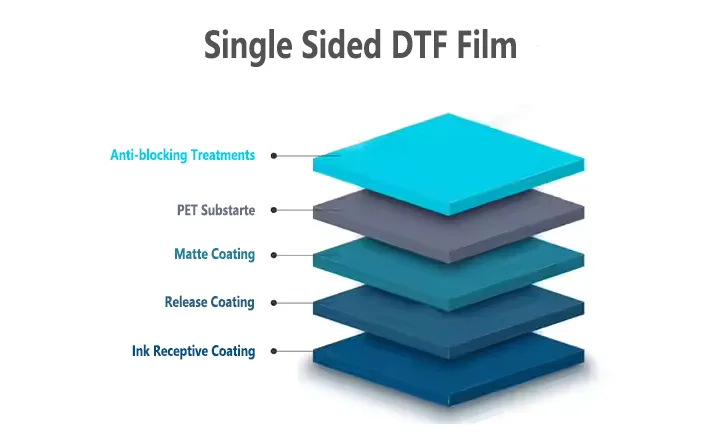

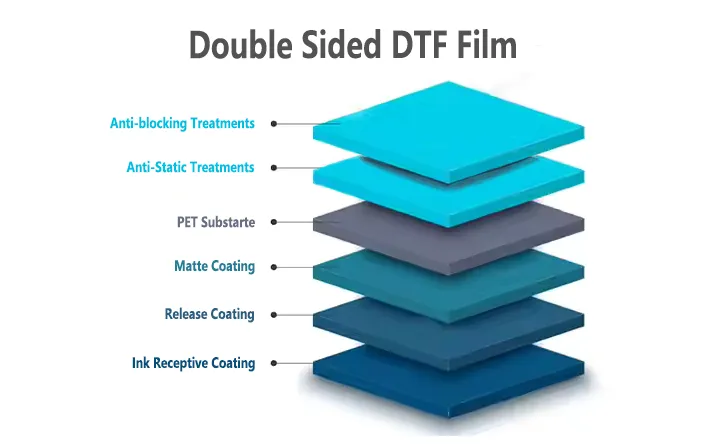

| Film Coating Type | Single Side / Double Side |

| Backside Treatment | Anti-slip / Anti-static (For Double Side) |

| Shipping Package Type | 1000 Sheets/Carton; 4 Rolls/Carton; Customized |

| Heat Press Temperature | 145 - 165℃ |

| Heat Press Time | 6 - 15 Seconds |

| Tensile Strength | > 150 MPa |

| Haze / Transparency | Matte coating ≈ 80% (haze ≈ 20 - 30%) |

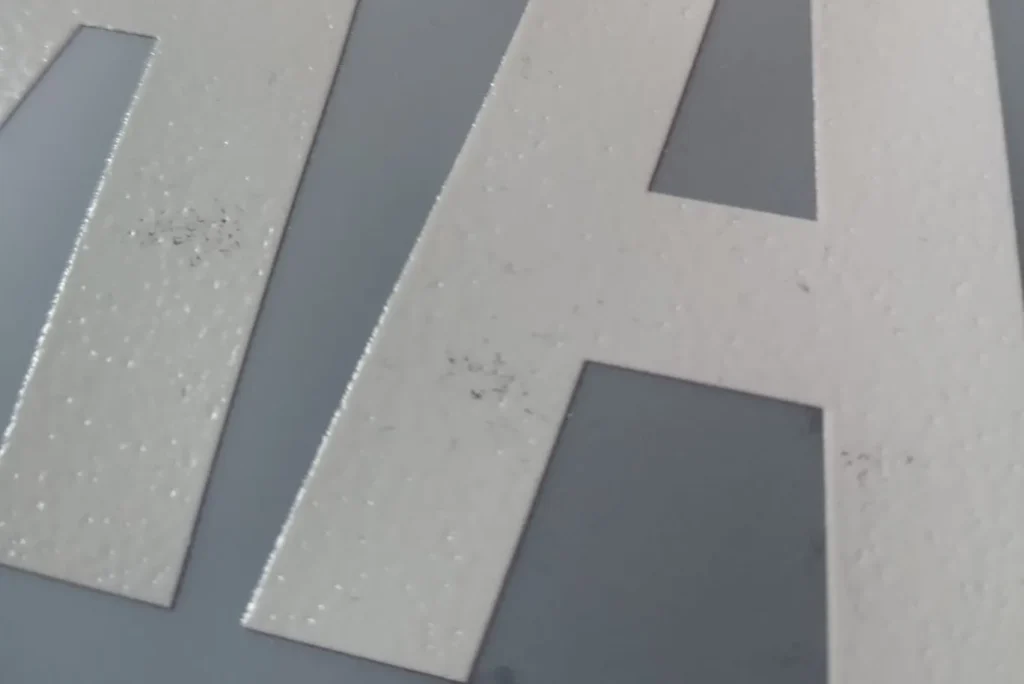

| Powder Adhesion Uniformity | High, Clean |

| Electrostatic Control Capability | Excellent |

| Dimensional Stability | Change rate ≈ 0 - 1% |

| Shrinkage Rate | ≤ 1% |

| Ink Absorption Performance | Matte > Glossy |

| Storage & Shelf Life | 15 - 25℃ / 40 - 60% RH; approx. 12 Months |

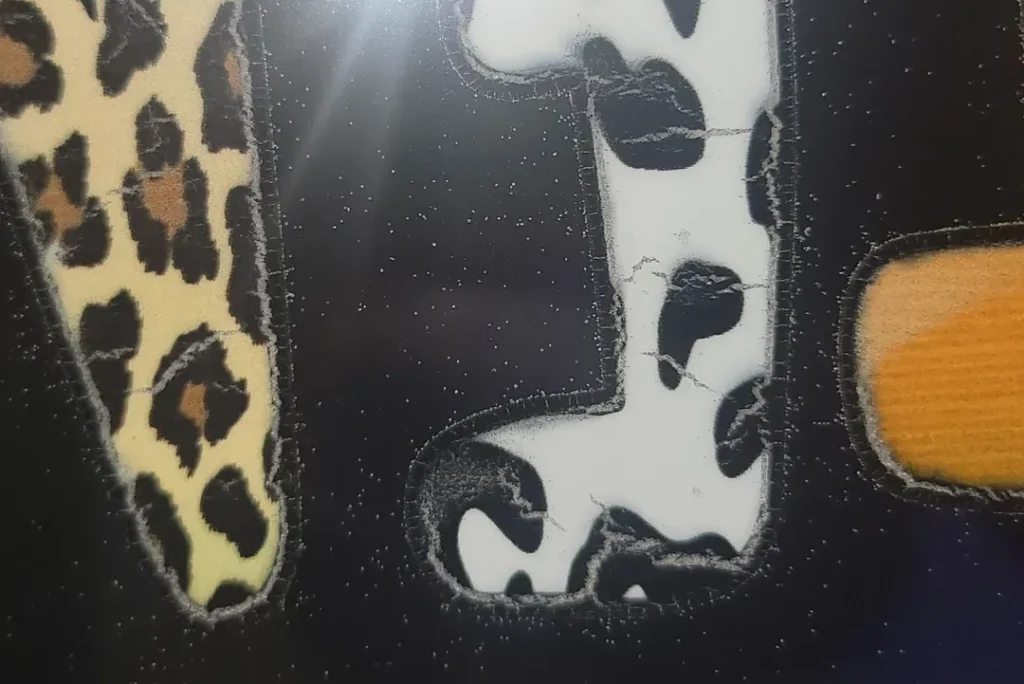

Specialty Film

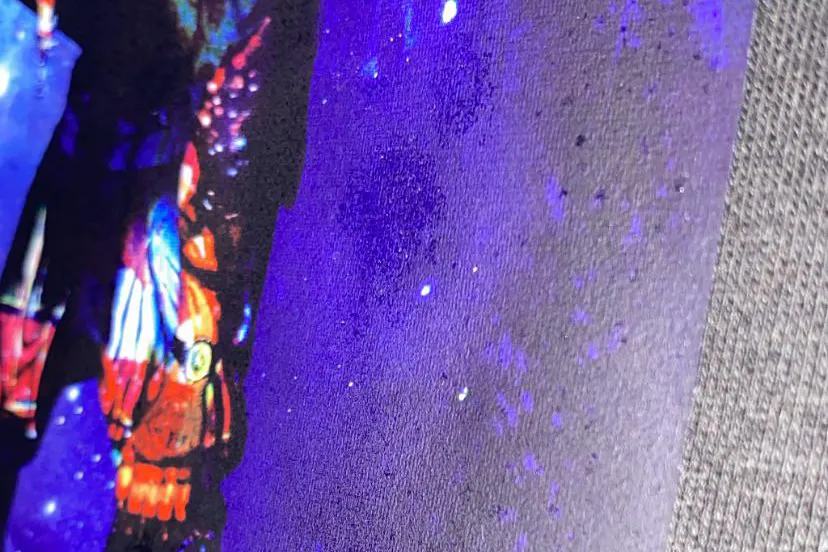

Product Test

Comparison

Explore Unique DTF Films

The single & double Sided difference

Double-sided film have an extra layer of Anti-slip and anti-static coating compared to single-sided film.

The ink absorption of double-sided masks is much better, with just one additional bake, the ink absorption performance can be 5% to 10% higher than that of single-sided masks. For more details, please visit What Is DTF Film Coating?

Our film dedicated to helping you avoid...

Frequently Asked Questions

What is the Hot Peel of DTF Film?

This is a peeling technique used in DTF transfer printing. The hot peel DTF film requires minimal pressure, temperature, and processing time, making it suitable for most fabrics. Generally, hot peel films are better suited for mass production, as you don’t have to wait for cooling, saving you that time.

What is the Cold Peel of DTF Film?

Unlike Hot Peel, Cold Peel requires longer pressure temperature and processing time, and it can handle transfer printing on certain special fabrics while effectively managing more intricate patterns.

Can the same DTF Transfer film be reused?

Due to the coating on DTF Film, which gets consumed during the transfer process, the same DTF Film cannot be reused. However, you can print the same image on the same Film, provided that you space them out properly and utilize methods such as cutting to make multiple uses of a single Film.

Does poor quality film affect the durability of the transfer?

Low-quality DTF film can directly affect the reproduction of images during the transfer process. However, overall durability after transfer is usually related to other factors as well; the quality of the film is just one aspect. It is unwise to overlook issues in other areas.

How should I store and handle DTF Film to maintain print quality?

To ensure consistent print performance, DTF film should be stored flat in a clean, dry, and temperature-stable environment (15–25°C, humidity 40–60%). Avoid exposure to direct sunlight, moisture, chemicals, or dust. Keep the film sealed when not in use, and always use older stock first to prevent quality issues from expiration. You can read This Article for more details.