DTF Printer Ink

Owcors offers DTF Ink in a variety of colors and capacities

Showing 1–9 of 22 results

-

PG1800 1000ML DTF Transfer Ink

$21.00 – $105.00Price range: $21.00 through $105.00This product has multiple variants. The options may be chosen on the product page -

PG1800 100ML DTF Transfer Ink

$2.50 – $12.50Price range: $2.50 through $12.50This product has multiple variants. The options may be chosen on the product page -

PG1800 500ML DTF Transfer Ink

$10.50 – $52.50Price range: $10.50 through $52.50This product has multiple variants. The options may be chosen on the product page -

PG2002 1000ML DTF Printing Ink

$21.00 – $168.00Price range: $21.00 through $168.00This product has multiple variants. The options may be chosen on the product page -

PG2002 100ML DTF Printing Ink

$2.50 – $20.00Price range: $2.50 through $20.00This product has multiple variants. The options may be chosen on the product page -

PG2002 500ML DTF Printing Ink

$10.50 – $84.00Price range: $10.50 through $84.00This product has multiple variants. The options may be chosen on the product page -

PG2003 1000ML DTF Pigment Ink

$25.00 – $175.00Price range: $25.00 through $175.00This product has multiple variants. The options may be chosen on the product page -

PG2003 100ML DTF Pigment Ink

$3.00 – $21.00Price range: $3.00 through $21.00This product has multiple variants. The options may be chosen on the product page -

PG2003 500ML DTF Pigment Ink

$12.50 – $87.50Price range: $12.50 through $87.50This product has multiple variants. The options may be chosen on the product page

Why choose Owcors DTF ink

Fine ink particles

Stable nozzle output

Clear color layering

Slow particle settling

Ultra-fine pigment particles ensure smooth ink flow and reduce the risk of clogging.

Wide color gamut with high fidelity — delivers sharp, vibrant, and accurate prints.

Stable formulation minimizes pigment settling, making storage and reuse hassle-free.

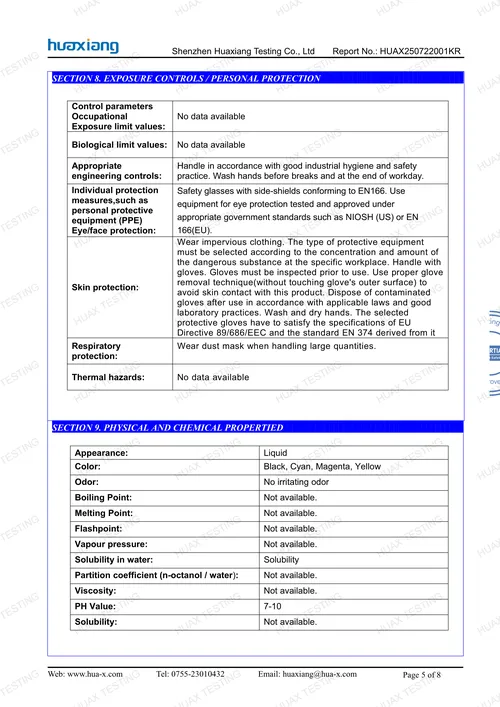

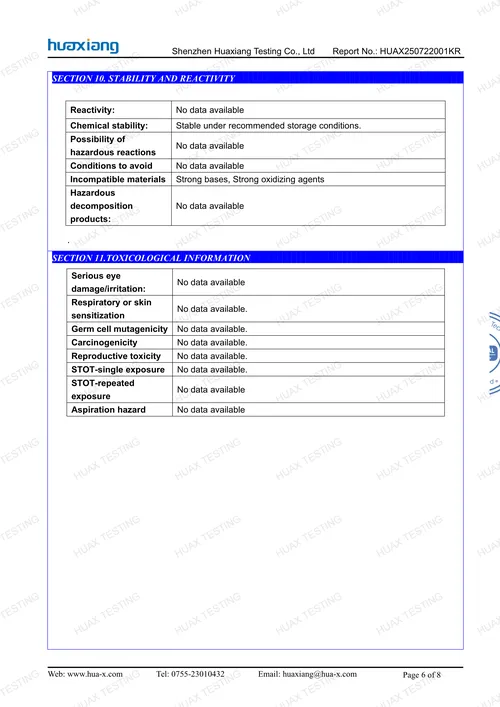

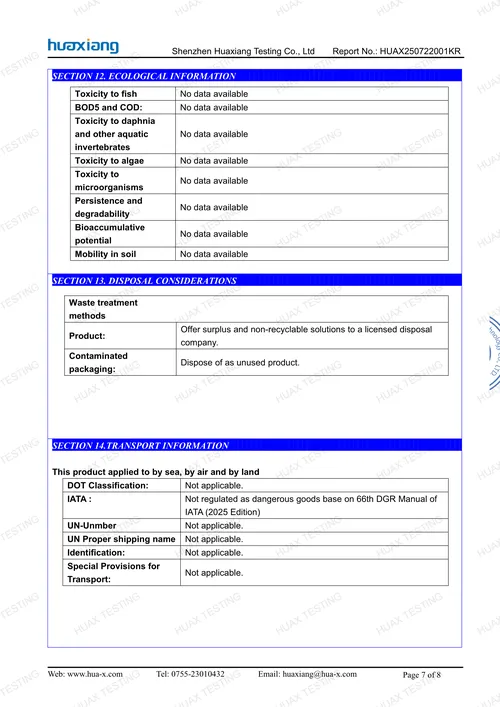

Specs & Tech Parameters

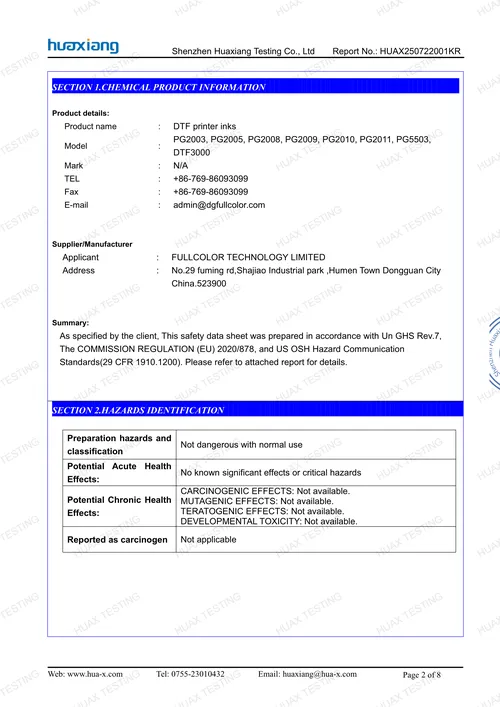

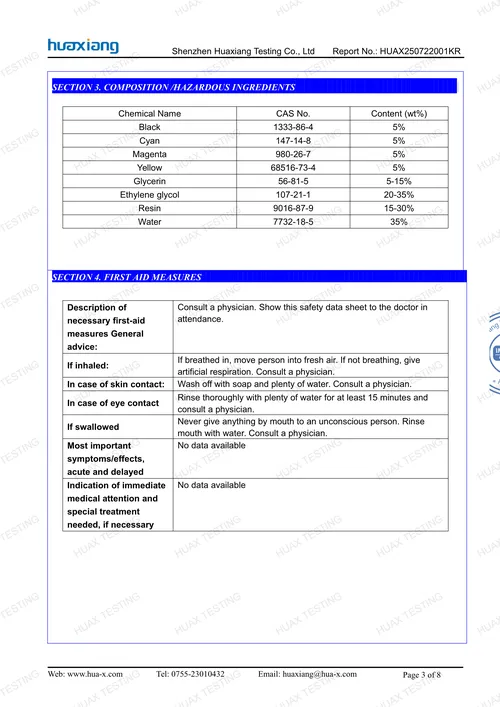

| Ink Model | PG1800 / PG2002 / PG2003 / PG2003A / PG2005 / PG2009 / PG2010 / PG2011 |

| Ink Type | Water-based Pigment ink |

| Color | C / M / Y / K / W / LC / LM / FO / FG / FM / FY |

| Volume | 1000ML / 500ML / 100ML / 5000ML Customized |

| Applicable Print Head | Epson I3200 / 4720 / L1800 / L805 / L8058 / L8550 / L1390 / XP600 |

| Particle Size | < 300nm |

| Shelf Life | 12 - 24 Months |

| Test Reports | See The Table Below. Contact Us For More Details |

| Package Spec | Bottle / Bag Available |

| Transport Package | Carton / Large Plastic Storage Bins / Assignable |

| PH | 8.0 - 9.2 |

| Density | 1.02 - 1.09 g/ml |

| Viscosity | 3.5 - 6 mPa.s |

| Surface Tension | 30 - 50 mN/m |

| Elongation | ≥ 200% |

| Coverage | 90% - 98% |

| Dry Rubbing Fastness Grade | Level 4 - 5 |

| Wet Rubbing Fastness Grade | Level 4 - 5 |

| Light Fastness Grade | Level 5 - 6 |

| Washing Fastness Grade | Level 4 - 5 |

Product Test

Comparison

Product Test

Comparison

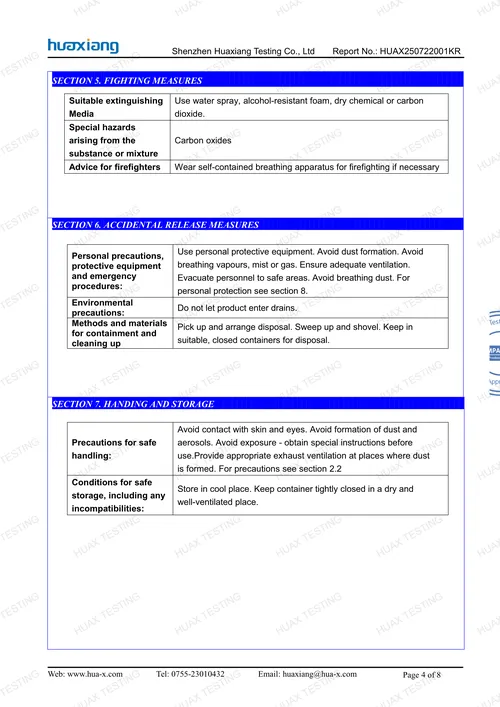

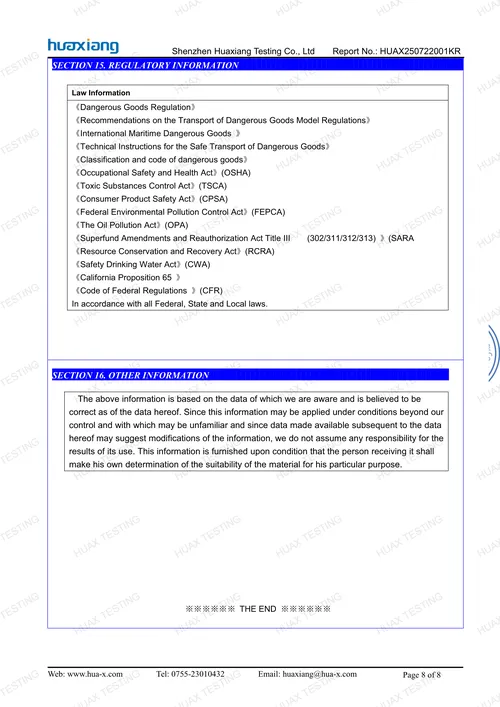

We Provide Various Certifications For DTF Ink

Frequently Asked Questions

Why does DTF ink fade?

The reasons for DTF printing ink fading may include issues with ink quality, improper transfer heating temperature and time, subpar coating quality, and environmental factors. You can refer to This Article for details on the causes and solutions. For your information, ink fading and ink dimming are caused by the same factor.

How should I store ink?

Generally, DTF ink requires specific temperature and humidity conditions for storage. If you can ensure a stable environment regarding these two factors, then you can consider storing it yourself. Understanding ink storage can facilitate long term use, read This Article to learn more.

How long is the shipping time?

We ship within 48 hours after order confirmation. Delivery typically takes 5 – 8 business days to most regions. For urgent or bulk orders, expedited shipping options are available — just let us know your needs when you submit your quote request.

Why can't white ink cover colored ink?

The reasons why white ink cannot cover colored ink usually involve issues with the ink itself, the printing equipment, the printing process, or the substrate or materials used. You can Click Here for the specific reasons.

How to solve the problem of white ink not covering color ink?

To address the issue of white ink not being able to cover colored ink, one can try optimizing the white ink formulation, checking and maintaining the equipment, adjusting the printing process, and improving substrate treatment. You can click the link from the previous question to see the solution.