DTF Hot Melt Powder

Owcors offers 6 types of DTF Powder to help you improve efficiency.

Showing all 6 results

-

2.2LB Anti-Static DTF Hot Melt Powder

$8.25Original price was: $8.25.$7.50Current price is: $7.50. -

2.2LB Black Medium DTF Transfer Powder

$12.10Original price was: $12.10.$11.00Current price is: $11.00. -

2.2LB Low-Temperature DTF Powder

$12.10Original price was: $12.10.$11.00Current price is: $11.00. -

2.2LB Ultra-Soft DTF BB Powder

$11.00Original price was: $11.00.$10.00Current price is: $10.00. -

2.2LB White Fine DTF Powder

$11.00Original price was: $11.00.$10.00Current price is: $10.00. -

2.2LB White Medium DTF Transfer Powder

$8.25Original price was: $8.25.$7.50Current price is: $7.50.

Our DTF Powders Top Features

Long-lasting adhesion

Bonds quickly and evenly to inks, providing long-lasting adhesion.

Tensile-Resistant Quality

Withstands a degree of continuous stretching without cracking or peeling.

Residue-Free Curing

Leaves no excess powder behind — clean edges, no dust, no mess.

Various Types Available

Antistatic, soft, and low-temp options available to meet diverse production.

Difference between the 6 Powders

White Fine Powder

- Particle size: 0 – 90 μm

- Melt point: 100 – 120 °C

- Use: Smooth and even fabric

- App: Cotton, Poplin, Woven

White Medium Powder

- Particle size: 90 – 170 μm

- Melt point: 120 – 140 °C

- Use: Rough fabric

- App: Denim, non-wovens, linens

Black Medium Powder

- Particle size: 90 – 170 μm

- Melt point: 120 – 140 °C

- Use: Dark Rough fabric

- App: Denim, non-wovens, linens

Anti-Static Powder

- Particle size: 100 – 160 μm

- Melt point: 125 – 135 °C

- Use: Available in most fabrics

- App: Cotton, Denim, Woven

Low-Temperature Powder

- Particle size: 90 – 140 μm

- Melt point: 85 – 90 °C

- Use: More suitable cotton fabrics

- App: Cotton

Ultra-Softness Powder

- Particle size: 0 – 90 μm

- Melt point: 100 – 120 °C

- Use: Smooth and even fabric

- App: Cotton, Poplin, Woven

Specs & Tech Parameters

| Powder Type | Medium-Fine Powder, Anti-Static, Low Temperature, Soft |

| Particle Size Range | 0 - 90 - 170μm |

| Melting Point | 85 - 110 ℃ |

| Powder Material | TPU / PES |

| Package Specs | 2.2LB / 1KG or Customized |

| Shipping Package Type | Carton |

| Baking Time | 2 - 3 Minutes |

| Storage & Shelf Life | Sealed, Dry And Cool Place 10 - 30℃, Humidity 40 - 60% |

| Density | 1.20 ± 0.02g/cm3 |

| Bonding Strength | 5 - 15 N/cm² |

| Washing Fastness | Level 4 - 5 |

| Tensile Property | ≥ 200% |

| Melting Viscosity | 2.5 - 3.5 Pa.s |

| Color Coverage | White: 5% - 12%; Black: 80% - 90% |

| Hot Pressing Time | 6 - 15 Second |

| Washing Temperature Range | 40 - 60℃ |

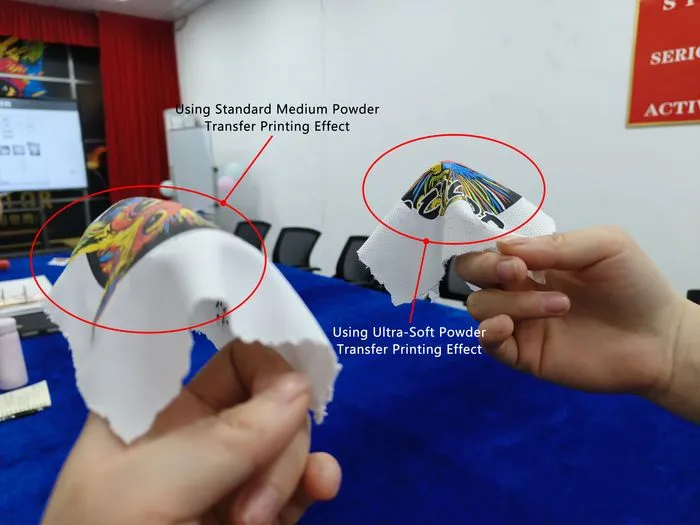

See the Difference Softness Can Make

- The fabric can be bent normally and smoothly, returning to the flexibility of the itself.

- The fabric is unable to bend as normal and the flexibility of the fabric itself is limited.

- The fabric's natural drape isn't apparent when supported from underneath.

- The flexibility of the fabric is showcased even more when it's supported from underneath.

Frequently Asked Questions

What is the melting point of DTF hot melt powder?

The melting point of hot melt powder will be different according to the material Low temperature powder 85-90 degrees melting point Common specification PU powder melting point in the range of 100-110 degrees. When baking, set the temperature 0-20 degrees higher than the melting point. See also: How To Cure DTF Powder With Oven?

How Should I Store DTF Heat Transfer Powder Properly?

To maintain the quality and performance of DTF hot melt powder, it should be stored at room temperature (15–30°C) with relative humidity between 40% and 60%. Avoid exposing the powder to direct sunlight, damp environments, or volatile chemicals, as these can affect its adhesive properties and cause contamination. After each use, reseal the packaging tightly to prevent moisture absorption. Also, be sure to use the powder within its shelf life and regularly check for signs of dust, oil, or degradation before use.

How to Solve The Problem of DTF Powder Sticky Powder?

Sticky powder issues can result from multiple factors, including excessive ink output, low baking temperature, unsuitable powder type, or poor film surface quality. To resolve this, ensure that the ink is properly dried before applying powder, use hot melt powder that matches your ink and film, and maintain a consistent baking temperature. Also, control ambient humidity between 40–60% to prevent moisture-related adhesion problems, and make sure the film surface is smooth and clean. For more information, see: DTF Powder “Sticky Powder” Phenomenon Causes And Solutions

What is the recommended baking temperature for DTF powder?

Baking temperature should be based on different heating and baking equipment to do micro-adjustment of the difference in temperature measurement, the conventional setting than the melting point of 0-20 degrees above the range can be.

Will the use of DTF transfer powder take into account the use of DTF jitterbugs?

Yes, most of the DTF Film will work in a DTF shaker when sprinkling DTF hotmelt powder, which requires you to set the baking temperature, which depends on the melting point of the hotmelt powder and is fine-tuned with reference to the baking effect.