This article will explore the differences between them, and why I believe it’s important to avoid confusing these two distinct products.

What Are DTF Ink And Sublimation Ink Exactly?

Before jumping into differences, let’s understand the basics:

- DTF (Direct-to-Film) Ink is pigment-based ink specially formulated to bond effectively onto films, transferring designs clearly onto various fabric types, particularly cotton and blends.

- Sublimation ink is a dye-based ink, though pigment-based options are now available as well. When heated, it transitions directly from a solid to a gas, allowing it to permeate synthetic fabrics and certain hard materials.

- Dye-based inks were more commonly used in the early days.

- Pigment inks currently require ink drying after application, even those quick-drying. The difference lies in the duration of the drying process.

The Key Differences Between DTF Ink And Sublimation Ink

Here’s where things get interesting:

1. Printing Process

DTF Ink and Sublimation Ink differ notably in their application processes:

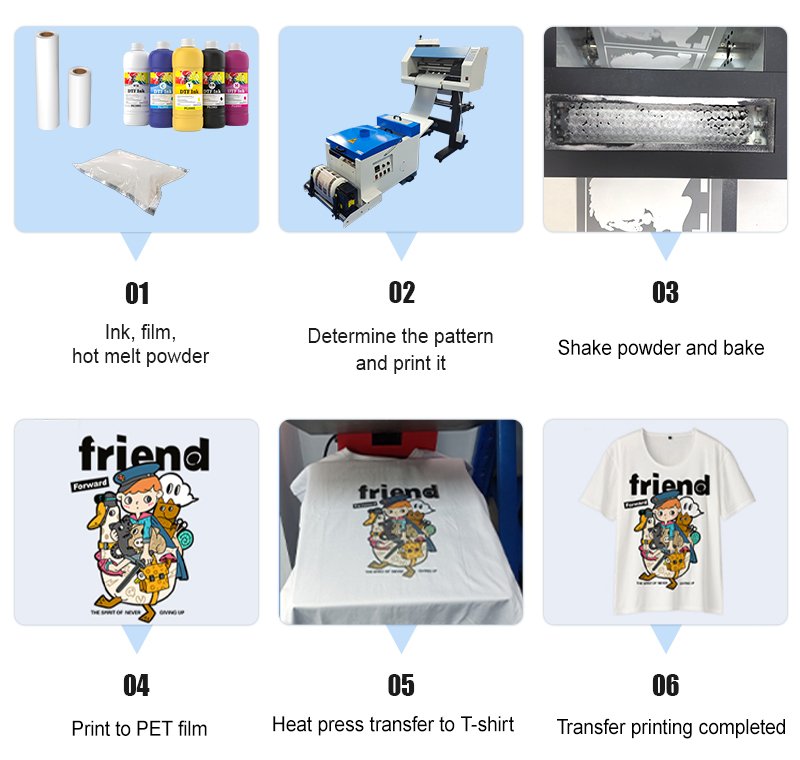

- DTF printing involves directly printing a design onto PET film, which is then coated with hot-melt powder and cured by baking. Finally, the design is transferred onto the fabric by heat pressing.

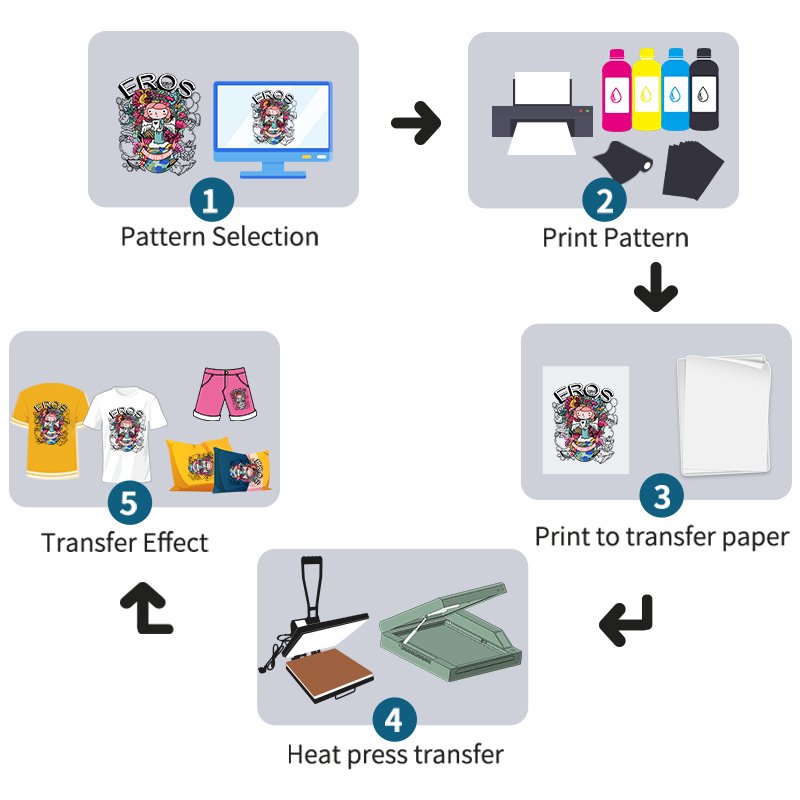

- Sublimation Printing prints onto sublimation transfer paper first, then uses heat to transform ink into gas, embedding directly into synthetic fabrics or polymer-coated surfaces.

- Certain hard materials, such as mugs, can be printed using corresponding transfer molds. If the material isn’t suitable, a coating can be applied to it for sublimation printing.

Both printing processes have their own specific consumables. It’s generally recommended to avoid mixing inks and printers. See also: Can You Use DTF Ink In Sublimation Printer.

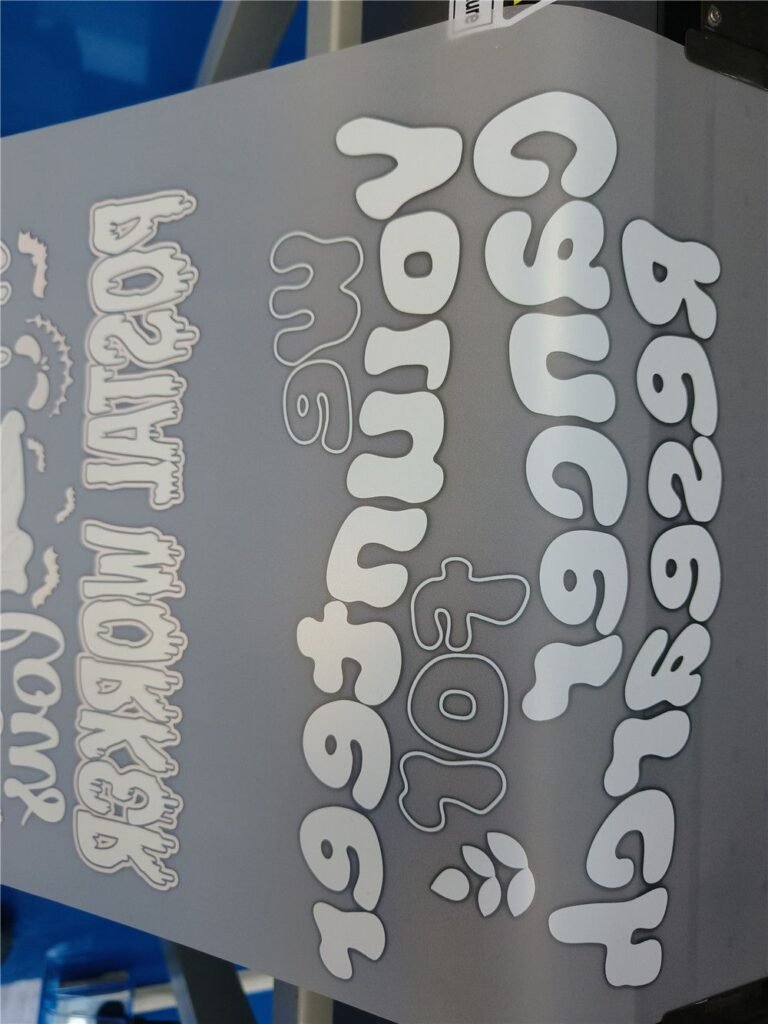

As in these two pictures below, the left one is clearly different from the right one.

2. Fabric Compatibility

Another significant difference is fabric compatibility:

- DTF ink is suitable for different fabric types. Overall much more suitable than heat sublimation inks.

- DTF printing technology emerged primarily to better replace the effectiveness of sublimation inks in fabric printing.

- Sublimation printing thrives on synthetic materials, especially polyester and nylon, but isn’t effective on natural fabrics like cotton.

- The primary reason for this phenomenon is that most fabrics cannot withstand the high temperatures involved in heat transfer printing. However, this is not the case for synthetic fabrics.

3. Color and White Ink Capability

- DTF Ink includes white ink, which allows for more versatility in printing. Variations in DTF powder can improve how it works on different fabric colors.

- The use of white ink can enhance the depth and dimension of a design.

- Sublimation inks lack white ink, restricting their use mainly to white or very light-colored fabrics.

- But there are many black ink types available for sublimation printing, such as light black and light light black.

This phenomenon will be particularly noticeable when you print black fabrics, see: How To Print DTF Ink On Black Shirt

4. Durability and Finish

Longevity and finish also separate these inks:

- DTF ink prints are located on the surface of the fabric with vibrant colors and sharp details. However, in terms of durability, since it is only a thin layer of adhesion on the fabric, there is a possibility of cracking or peeling.

- Good ink can enhance the durability, but it’s not permanent.

- As for sublimation ink, it sublimates directly and permeates the fabric, so there is no thin layer on the surface. However, this does not mean that sublimation ink will not fade.

- Similarly, good sublimation ink helps prevent fading.

How DTF Ink And Sublimation Ink Work Differently

Traditionally, there’s a distinction between the two in terms of technique.

DTF Printing Process:

- Print your design on PET film using a DTF printer and DTF ink.

- Apply hot melt powder to the wet ink.

- Bake the film in a special oven to melt the powder.

- Use a heat press to transfer the design onto fabric.

See also: How To Print On DTF Transfer Film?

Sublimation Printing Process:

- Print your image on sublimation paper using dye-based sublimation ink.

- Heat press it onto a suitable substrate.

- The ink turns into gas and infuses into the material.

The difference between the two in terms of consumable usage is also quite obvious from the results.

Choosing Between DTF Ink And Sublimation Ink

Both are similar in cost, so choosing between DTF and sublimation ink depends on your specific printing needs:

If you’re looking to print on pure cotton garments like T-shirts, DTF is your best bet. There are many modified printer options available now, some even allowing you to switch between two different printing modes simultaneously.

Therefore, when choosing, you don’t have to overthink it. If you want your design to cover the entire fabric, then use sublimation ink.

As long as your business is looking to print on fabric, it’s appropriate to prioritize DTF. After all, they are definitively different in terms of consumables used.

At this stage, there will be more groups using the heat sublimation process than DTF.DTF as a new process, there are still a lot of problems to be faced. If you are looking for stability, you can consider getting an EPSON sublimation printer and try to modify it to accept DTF as well as thermal sublimation mode!