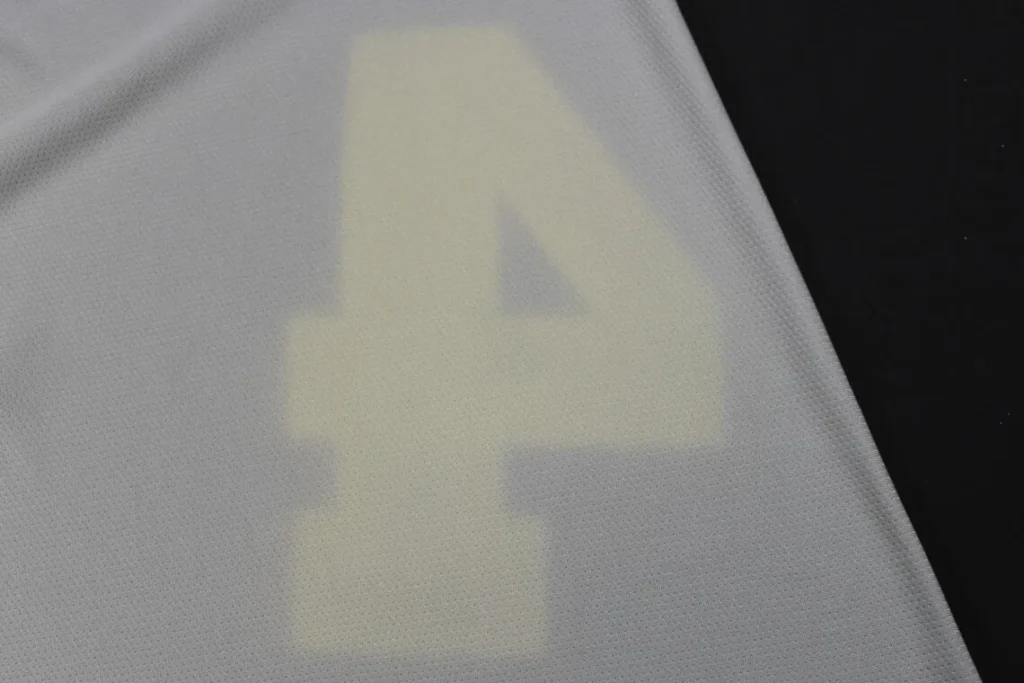

Use of sublimation inks caused “streaking” problems

Stripe problem can be said to be a frequent phenomenon in the printing industry, not only will appear in the sublimation printing. Generally this situation is directly related to the sublimation ink, followed by the printer settings.

Streaks caused by the printing of the root cause of the problem is the print head clogged. Resulting in the nozzle can not print the complete output of ink. Streaks can also be interpreted as a “lack of ink”, where the part that should be printed is not completely printed.

Why do you say that the problem of streaks is related to the ink? In fact, the reason is that whether the ink is too much precipitation for the print head clogging has a great impact. If your ink for a long time before opening, then its pigment particles have long been precipitated. Precipitated particles in the actual use of a large number of aggregation will cause clogging.

Improper storage or poor quality of ink is more likely to clogging, and clogging will result in insufficient ink output, resulting in “streaky” printing phenomenon.

How to solve the “streak” problem?

First of all you need to make sure that the ink is still within its shelf life. Don’t use ink that is not within its shelf life, it will waste your time and increase your cost.

Secondly you need to maintain your prints more, regularly check the settings of your printer and the corresponding hardware. If a clog occurs in the moment, it means you’ll need to perform maintenance all the time afterward, and more often.

Finally, if you find that neither of the above is the cause of the “streaking” problem, then you need to look at the paper. Poor quality paper can also cause this, so just replace it with better paper.

Problems with “ghosting” after using sublimation inks

The problem of ghosting is more because of the sublimation paper, and the reason why sublimation ink should be mentioned here is that the ink can also induce ghosting problems when it is not dry enough.

Double Shading is the blurring of the printed image, like a shadow. The trouble with ghosting is that once it occurs, it means that all your previous printing efforts have been wasted.

The root cause of most ghosting problems is that when using a heat press transfer. The transfer paper does not fit snugly against the substrate, causing the transfer to fail. The next problem is that the ink is not dry, and the ink remains wet during the heat press transfer, causing ghosting on the substrate.

How to solve the “ghosting” problem

Solving the ghosting problem only requires you to keep two things in mind: determine the temperature and time needed for the heat press transfer, and make sure the sublimation ink is sufficiently dry.

Just test the substrate as many times as possible to determine the conditions required for the transfer.

Sublimation inks “slow drying” problem after printing

Generally, the ink on the transfer paper is not dry, and there is a possibility of overflow of pattern edges or color deviation on the substrate after transfer.

Slow ink drying is usually related to the paper and the ink itself. After the ink is printed on the paper, the ink itself will slow down the drying process. This can be felt by using different sublimation inks.

If you know definitively that this brand of ink is fine in terms of drying efficiency, then you need to consider whether there is something wrong with the sublimation paper. Poor materials used to make sublimation paper can also affect the drying efficiency of the ink. Even if it can help you with the transfer!

How to solve the “slow drying” problem

If you don’t really want to change to a different sublimation paper. Then you may want to consider standing still for a while after the ink is printed onto the paper and waiting for the ink to dry naturally on the paper. The exact drying time will depend on your production records, with different results in different environments.

If you don’t have the time to wait for it to dry naturally, then I would recommend changing to a better sublimation paper and sublimation ink. Some inks can dry more quickly due to their composition. While some sublimation papers have a stronger ability to absorb ink and also have a fast drying effect.

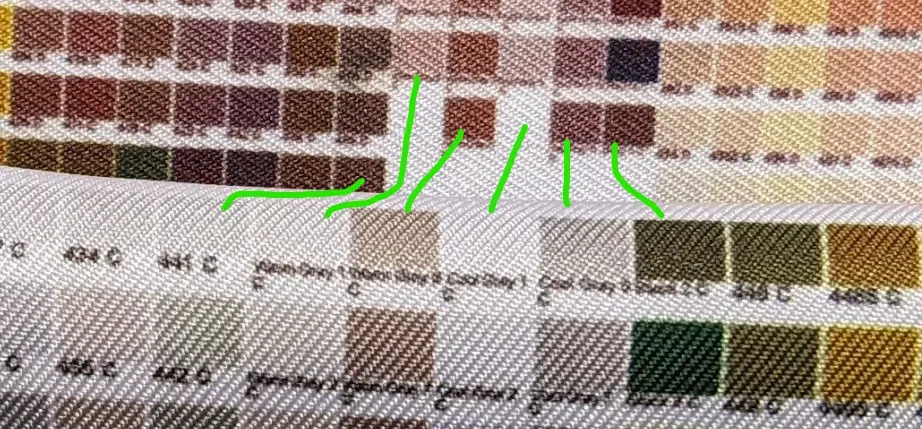

Problems with “Color Accuracy” after transfer

Obviously I printed magenta, but the actual transfer to the substrate, but the results show “off-color”, I believe this is often encountered by the problem.

Similar problems are summarized in fact is the problem of color accuracy. The cause of this problem with the ink and printer are related. Ink composition does not work or past the shelf life, it will lead to color accuracy there are differences.

Incorrect printer settings may also appear color deviation, especially like frequent replacement of different brands of sublimation ink. Frequent changes can lead to mixing of inks, which in turn can lead to incorrect color accuracy.

How to solve the problem of incorrect “Color Accuracy”?

First you need to adjust the printer settings, test a few more times to see if the color is accurate, repeated debugging after the color is still inaccurate to consider the ink problem.

At this point you can change a bottle of ink to see if the color is the same precise problem. One by one until the root cause of the problem!

The “durability” issue that needs to be confronted

Printing with sublimation ink is truly amazing, but it is not a panacea! In the printing industry, sublimation printing does have some advantages in terms of durability of the product after printing. But the real truth is that it has its drawbacks as well.

The issue of durability usually encompasses resistance to washing, UV rays, temperature, chemical reactions, scratching and abrasion. The fading of colors over time that we often talk about is actually a combination between these durability.

There are temperatures, UV rays, chemical reactions, scratching and abrasion, and washing everywhere in life. So the durability issue can only be met with specific prerequisites, and is not adaptable to everything. It depends on what application scenarios you prefer for your printed products.