What Are Sublimation Consumables?

Sublimation consumables are a type of consumable that is used exclusively in dye sublimation printers. This type of consumable is divided into two categories: ink and paper. Where the paper is divided into sublimation paper and heat transfer paper.

The main difference between sublimation paper and heat transfer paper is the difference in application, as follows:

- Sublimation paper: can be printing on polyester fabrics and items with polymer coatings, and the “embossed” feeling is not obvious after the transfer.

- Heat transfer paper: can only be printed on cotton, polyester strips and blended fabrics, with an obvious “embossed” feeling after transfer.

If you want to learn more about the difference between sublimation paper and heat transfer paper, check out this article.

Like DTF printing and UV DTF printing, sublimation printing have a unique process. The dye sublimation printing process primarily involves sublimating the ink printed on the paper onto the substrate with the help of heat. This is a process of evaporation from a solid state to a gaseous state.

Therefore, sublimation supplies are not to be mixed with other printing materials and are not suitable for printers that are not dye-sublimation printers.

How To Judge The Quality Of Sublimation Consumables

Evaluating ink consistency and color accuracy

Sublimation inks that are compatible are no worse than sublimation inks for specific printer models. The quality of the ink is mainly based on the color accuracy of the ink, the color is correct in order to accurately restore the pattern design. Poor quality ink may change color after high temperature sublimation, resulting in a pattern transfer that does not meet the requirements.

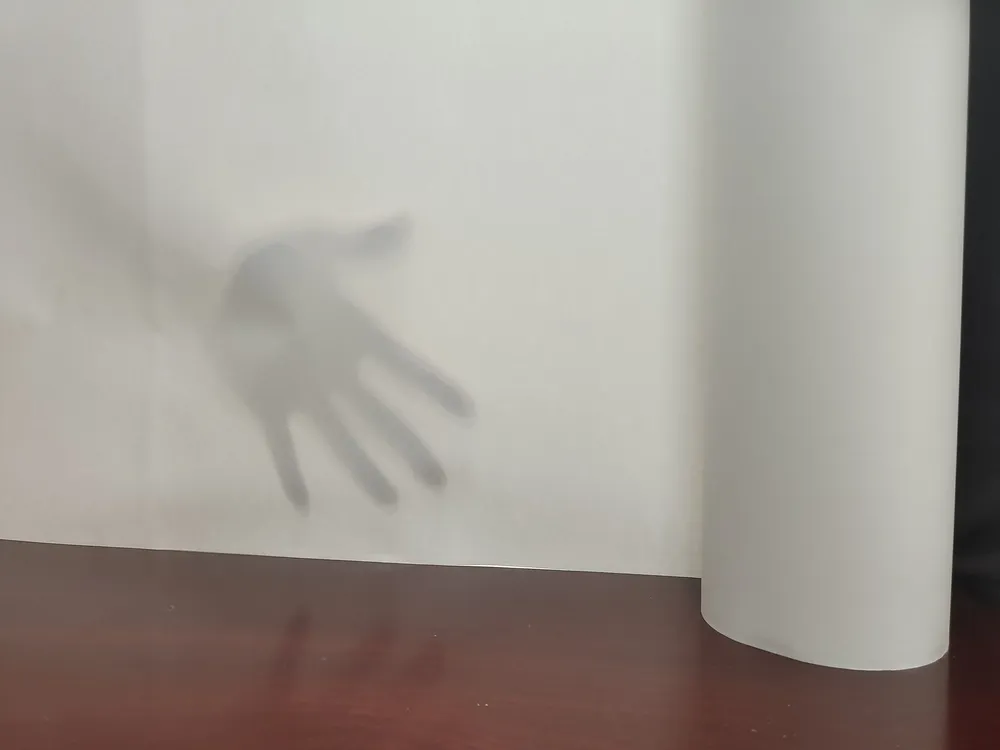

Paper’s ability to absorb ink

Paper that does not have the ability to absorb ink will shift or even leak ink when printed onto the paper. It fails when you flip the paper over to prepare it for sublimation printing on the printer. Secondly, some papers can keep the ink from shifting, but after transferring the pattern and realizing that the pattern on the substrate is not as complete as you designed it to be in the first place, this is also evidence of the paper’s poor ink-absorbing ability.

Sublimation supplies compatibility

Sublimation ink cannot be used in other types of printers, and the same goes for sublimation paper. However, even if all the inks and papers used are those that can be used in sublimation printers, they are not necessarily fully compatible. Individual dye-sublimation printers require specific inks to work, and these specific inks may not be suitable for compatible paper. In general, paper has a broader compatibility, while ink depends on the printer model. Good quality ink and paper are not too incompatible.

What Industries Need Sublimation Consumables

Clothing industry

If you want to print a design on a polyester fiber garment, then you will definitely use heat sublimation supplies. There is a difference between DTF printing, which cannot be printed on stretchy garment materials, and dye sublimation printing, which can be printed on stretchy garment materials.

Gift industry

Sublimation printing is possible for items such as mugs, cell phone cases, keychains (canvas material). If you are engaged in these gift-related industries, you will also use sublimation supplies (except for getting someone else to do the printing for you).

Outdoor products industry

Common outdoor signs, flags, and banners can also be done using sublimation printing. As long as the sublimation supplies you use are fine, the graphics on these products can generally remain colorfast for a long time. The color fades after a while, which means the supplies are not of good quality.

Maximizing Results with Sublimation Consumables

Choose the right printing substrate

Sublimation ink includes a type of ink called “high-penetration heat transfer” ink, specifically designed for printing on elastic (stretchable) fabrics. Using regular sublimation ink on this substrate results in incomplete transfers when the fabric is stretched. Therefore, you need to ensure that your consumables are compatible with the current printing medium.

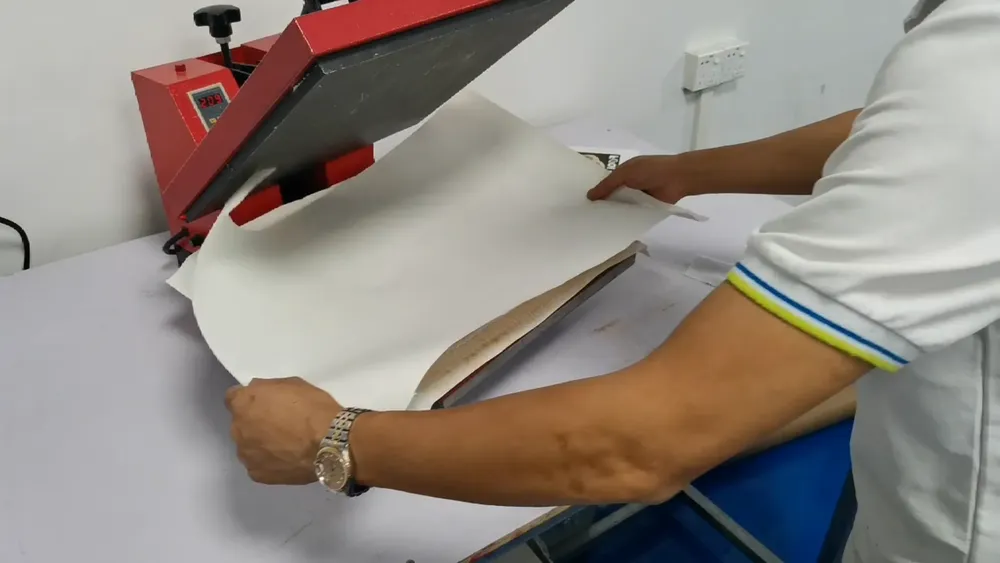

Place a protective sheet up the transfer

Using a heat press is great when the printer does not have the ability to print and sublimate in one. You can line the paper to be transferred with protective paper, which helps prevent the ink from ghosting during the press transfer process. It also helps to avoid the problem of insufficient hot press temperature.

Adjusting printer settings

As long as the consumables themselves are fine, you can ensure print quality by adjusting the printer settings. Sometimes, the transfer pattern doesn’t match the design colors because of incorrect printer settings, not necessarily a consumables problem.

Conclusion

Sublimation consumables are only suitable for dye-sublimation printers. Consumable quality is judged by their application in the sublimation printing process. Ink is assessed by color, and paper by ink absorption. Currently, sublimation printing mainly focuses on the markets of (specific) apparel, gifts, and outdoor products. We believe that future technological advancements will bring it even more opportunities!