UV DTF ink and AB film for stickers, welcome to contact for bulk discount.

Two Types of UV DTF Supplies by Owcors

Our consumables are designed for UV direct-to-film(DTF) printing, as opposed to UV printing that cures directly to the substrate.

Our UV DTF inks are divided into inks for crystal labels and faux embroidery inks, process to produce a “stereoscopic” effect.

UV DTF AB Film is specially designed for the UV crystal labeling process and can cope with the transfer on most hard substrates.

Supplies designed for crystal label stickers

Our UV8035 ink and AB film can make three-dimensional glossy feeling, continuous output without clogging, easy to paste and peel, simple operation without stagnation.

Consumables designed for Faux Embroidery Garment Print

Designed for textiles, suitable for high-end customized products. The best alternative to manual embroidery products.

UV DTF Printing Applications Intro

Unlike DTF printing and sublimation printing, UV DTF printing is more involved.

- UV DTF printing can be done on the following hard materials: ceramics, acrylics, glass, metal, plastic, silicone, wood, etc. It improves on the limitations of UV printing, which is limited to flat surfaces, and can be used to print more personalized shapes.

- UV DTF printing can also be realized on some soft and thick materials, such as leather and canvas. However, it is not suitable for materials with tensile force.

- UV DTF printing is often used in gift packaging, promotional products and other industries, involving a wide range of printable items. With hot stamping technology can also be aluminum foil, gold foil, silver foil hot press transfer to the items.

- The crystal label UV printing process is not a "omnipotent" process. It is not suitable for substrates that have a noticeably bumpy surface, nor is it suitable for prints that are typically used in outdoor scenes.

Optimal use of UV Printer Supplies

Printing supplies are right, but not using it well leads to poor results.

Considerations When Purchasing Ultraviolet printing supplies

While the printing equipment is superior, poor supplies can also affect the printing results. If you are not sure you can also consider using a free sample service.

Adhesion Strength

Both ink and film have adhesion properties. Determine the strength of the adhesion between the ink and film, and the adhesion of the film to the final substrate to determine which part of the process is at fault.

Durability & Longevity

The durability of the printed product is related to the consumables used. Factors such as scratch and wash resistance are linked to ink quality, while high-temperature resistance depends on the film quality.

Color Vibrancy & Accuracy

Good printing equipment can be a good judge of the quality of the supplies. If the ink is not good, the color levels of the transferred image may not be rich enough, and if the film is not good..

Curing speed & consump

If the printing equipment is too old, the wavelength of the ink and the wavelength of the UV lamp may not match, and the color and resistance of the ink will be weakened after printing, and secondly.

Ways to use UV DTF Printing supplies

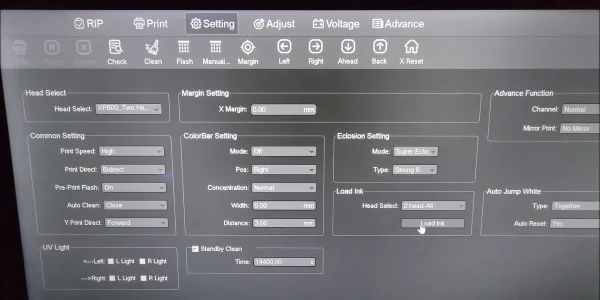

Step 1: After designing the image, fill the cartridge with CMYK ink, white ink and varnish, making sure that the printer is compatible with the UV DTF ink used.

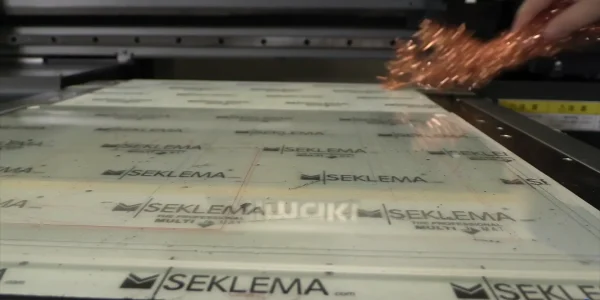

Step 2: Place the A-side of the UV DTF film on the flat surface of the printing device (the film loading method of the device may be different, so please refer to the corresponding operating instructions) for printing.

Step 3: After printing the design on film A, use the laminator to laminate film A with film B. Some devices will automatically laminate as they print, at which point you just need to cut.

Step 4: Peel off film A after lamination and transfer immediately with film B. Make sure that the film adheres completely to the surface of the substrate (clean the surface first), and flatten the film.