UV DTF AB Film

Offers 2 common UV DTF Films, and sizes can also be customized.

Showing all 4 results

-

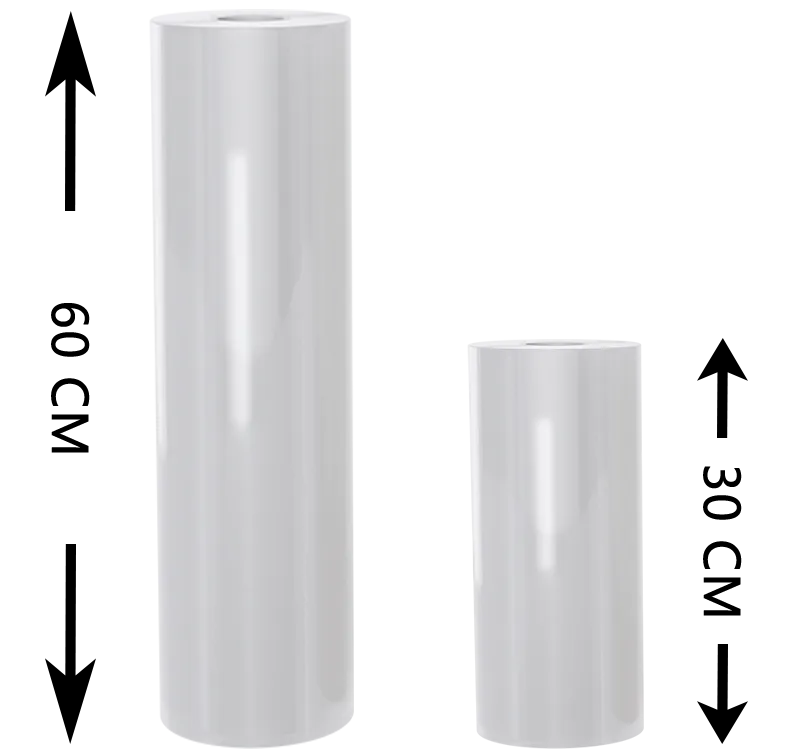

30CM UV DTF AB Film

$53.90Original price was: $53.90.$49.00Current price is: $49.00. -

30CM UV DTF Film

$53.90Original price was: $53.90.$49.00Current price is: $49.00. -

60CM UV DTF AB Film

$105.60Original price was: $105.60.$96.00Current price is: $96.00. -

60CM UV DTF Film

$105.60Original price was: $105.60.$96.00Current price is: $96.00.

Why Owcors UV DTF AB Film?

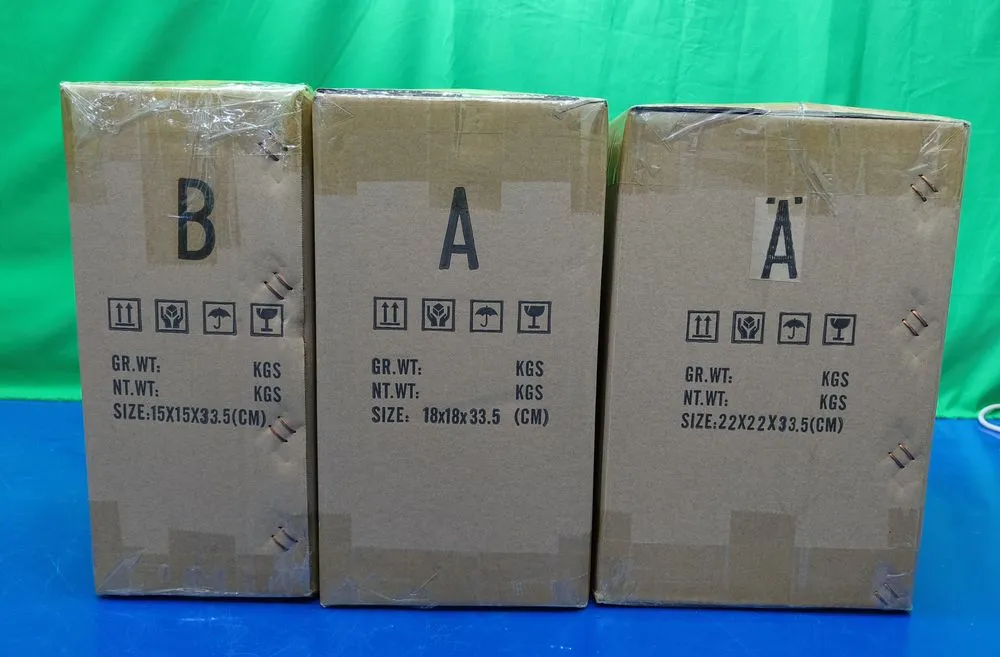

Printable A Film - Clear

Strong ink absorption layer, clear base, vivid color output, clearer transfer.

Printable A Film - White

White color, easy peel, no residue, ideal for industries with frequent pasting.

Standard B Film

High-temp resistant, no glue overflow, smooth final release layer without residue.

Strong ink absorption layer ensures vivid ink gradation.

Reliable adhesion, no glue seepage, residue-free removal.

Clear transfer, no ink residue, smooth peeling non-blocking.

Specifications are customizable, special styles are available.

UV DTF AB Film Usage Process

1. Printing A-film, laminat A/B-film

2. Tear off film A

3. Press down with Film B facing up

4. Tear off film B

UV DTF Film Application Cases

Frequently Asked Questions

How to store UV DTF AB Film?

It is recommended that DTF membranes be stored at 15°C to 25°C. The relative humidity should be maintained between 40% and 60%. Corresponding temperatures and humidities are also followed when working. For more details, please refer to the DTF Film product page. The storage details are similar except for the use.

What is UV DTF AB Film made of?

Basically are made of polymer materials, different customized styles have different production processes, the film coating process will also vary, the main distinction between the resistance and quality (thickness).

What sizes of UV DTF Film are available?

The market is dominated by 30cm and 60cm, but there are options for customization if your printing device can accommodate non-standard sized films.

How to Judge the Quality of UV DTF AB Film?

When judging the quality of UV DTF AB film, several key factors should be considered. First, ink adhesion plays a vital role—if it’s too strong, the film may jam or leave ink marks during peeling; if too weak, color may bleed through. Second, poor film quality can lead to wrinkles or bubbles, especially when the film lacks sufficient heat resistance. Third, dull or faded prints often result from a subpar ink-absorbing layer on the A film, which affects color vibrancy. Lastly, peeling difficulty is also a sign of film quality—high-tack A film may be harder to remove than low-tack options, and a well-balanced AB film should ensure both firm adhesion and easy peeling to maintain production efficiency.

What is the lamination temperature of the AB film?

There are high temperature and low temperature films on the market. High temperature is generally about 90-95 degrees, Low temperature is generally in the 40-45 degrees or so.