I won’t deny that some inks do indeed cause color deviation due to quality problems. However, to pinpoint the problem more accurately, it’s more important to first understand this phenomenon and identify its causes. Therefore, this article will focus on guiding everyone to understand the color deviation phenomenon that occurs during printing.

What Is Color Deviation in DTF Ink Printing?

In DTF printing, color deviation refers to the mismatch between the intended colors and the colors actually produced by the printer. It means the printer isn’t accurately reproducing colors; for example, reds might appear faded, or blacks might look more like gray. This not only affects the visual appeal of the design but can also ruin an entire print run if not addressed promptly.

The issue is often more complex than simply “bad ink.” It could involve incorrect software configurations, printhead issues, or mismatched profiles. But don’t worry, in most cases, if it returns to normal after troubleshooting, it indicates that the ink quality is not the cause.

Determining problems with ink quality has a certain relationship with production and storage. In terms of production, different manufacturers have different strategies. But in terms of storage, the same conditions are basically followed. If you want to know about DTF ink storage, read: DTF Pigment Inks Storage Guide

By the way, problems caused by ink “broken” are a different concept than color deviation. Although they seem very similar. But the causes of the problems are different. See also: What Should I Do If The DTF Ink Breaks During Printing?

Understand Your Software Settings and Record Evidence

Typically, when you encounter a color cast with DTF ink, you should document everything before you officially begin troubleshooting. First, identify what your current print settings are, which can be viewed in the printing software. Different software programs have different settings, and not everyone uses the exact same settings to resolve color cast issues.

Take the time to record a video or take screenshots illustrating your current print settings and the output result. This will not only help you with comparisons later, but if you end up needing help from a technician or support team, these visual references will make it easier for them to assist you.

How to Test and Diagnose Color Issues in DTF Ink Printing

Once you’ve documented the current issues, you can start troubleshooting. Here are some simple yet effective self-checking methods:

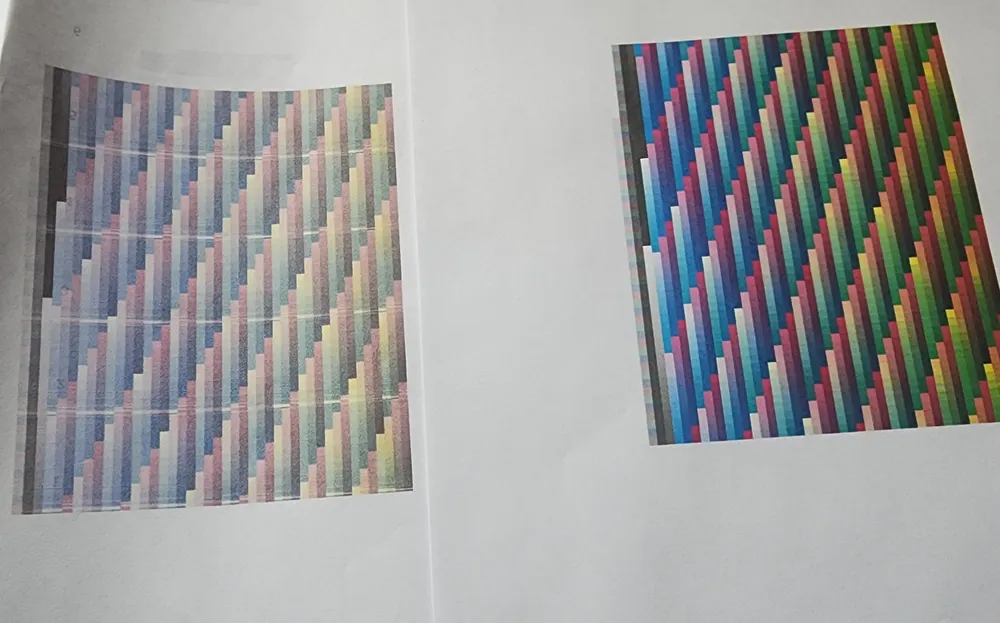

- Reprint a previously well-configured file: If you have a design that printed well in the past, try printing it again using the same materials and settings. This can help you determine if the issue is specific to the file or caused by something else.

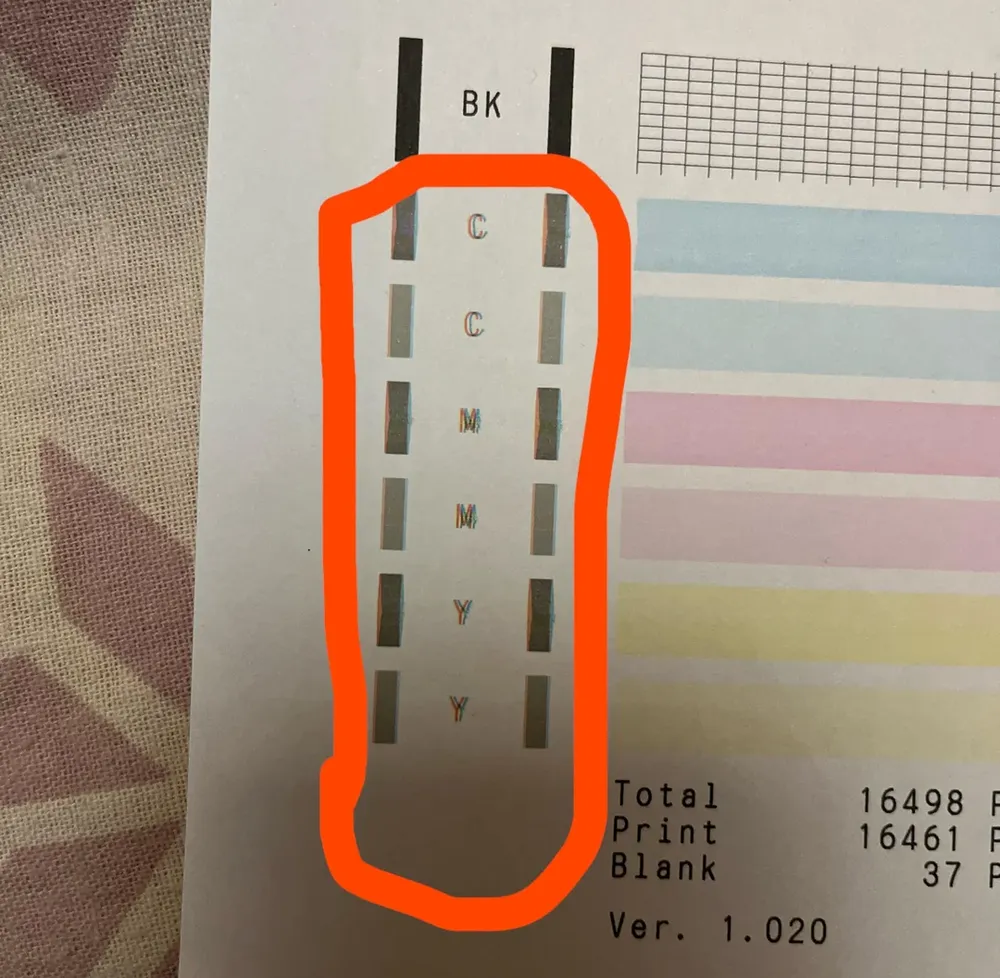

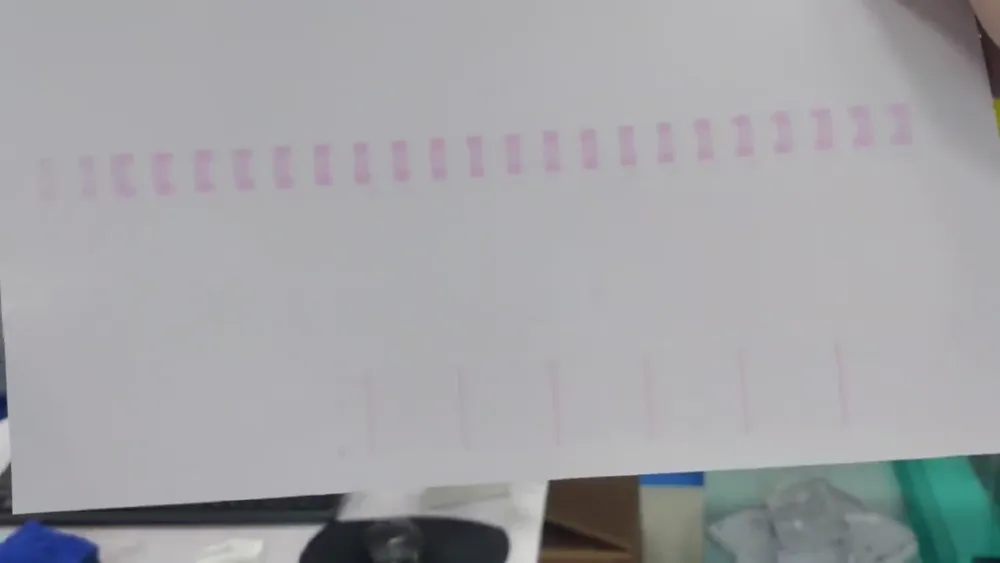

- Run a nozzle test print: Most DTF printers have a built-in nozzle check function. Print a test pattern and check for any missing lines or gaps, which would indicate that your printhead may be clogged or malfunctioning.

- Check ink flow and levels: See if the ink output you set in the software matches the actual output. Appropriately reduce the output to observe the actual situation. Low ink levels or air bubbles in the lines can also cause inconsistent color output.

In general, after these three tests, you should be able to determine the source of the problem, whether it’s a mechanical issue, a software issue, or a color deviation caused by something else.

Solutions for Fixing Color Deviation in DTF Ink Printing

Based on tests conducted by our engineers, color deviations in DTF ink printing are typically more related to the print software settings. Different pattern designs require different software configurations; otherwise, the printer device cannot perform to its full potential. Here are three of the most common solutions:

Verify ICC Profile and Driver Settings

One of the main reasons for color shifts in DTF ink printing is incorrect configuration or missing ICC profiles. These profiles act as color translators, helping the printer accurately interpret the colors of the design. If they are adjusted or removed, reinstalling or re-importing the correct ICC profile may solve the problem.

Check Software Print Settings and Ink Order

Sometimes, the print software settings may have been unknowingly changed, especially in cases of frequent printing operations. Verify that the printing mode, resolution, and ink order are consistent with the original settings. Any mismatch in the ink channel sequence (such as white under color versus color over white) can cause color distortion.

Rebuild or Recreate the ICC Profile

If you have changed ink brands, film types, or other consumables, the old ICC profile may no longer be applicable. Different inks are adapted to different profiles, and dedicated configuration profiles are adapted to dedicated inks. In this case, you may need to recreate a custom ICC profile to match your current setup. This usually requires professional color calibration tools and software.

While this step may sound technical, many DTF printer suppliers or service providers offer ICC profile creation services, or at least provide guidance.