The DTF printing process usually prints color first and then white. Therefore, ink bleed occurs more often after white ink printing and occasionally after color ink printing.

Understanding Why DTF Film Ink Bleed Happens

Problems With The Ink-Absorbing Layer

DTF film is coated with a specialized ink-absorbent coating that is the main difference between it and normal film. It holds the ink in place during the printing process. When this coating is defective, too thin, or incompatible with the type of ink, the film may run white ink because it does not absorb the ink properly.

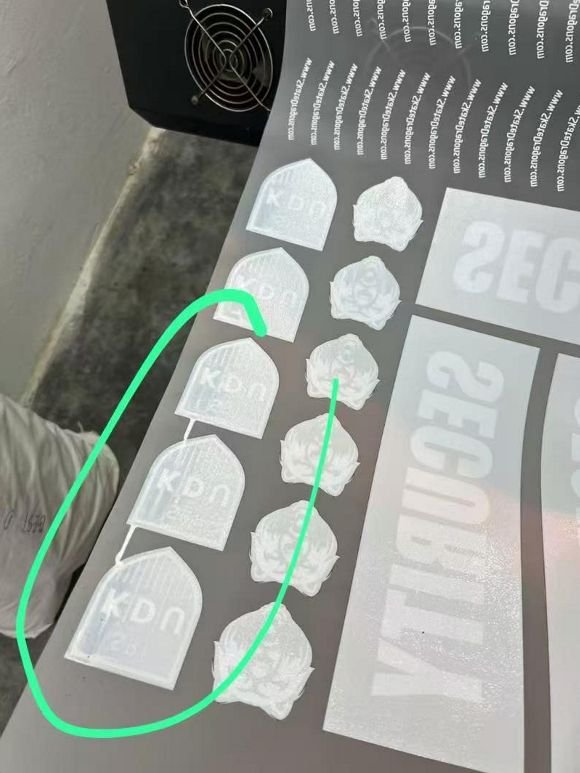

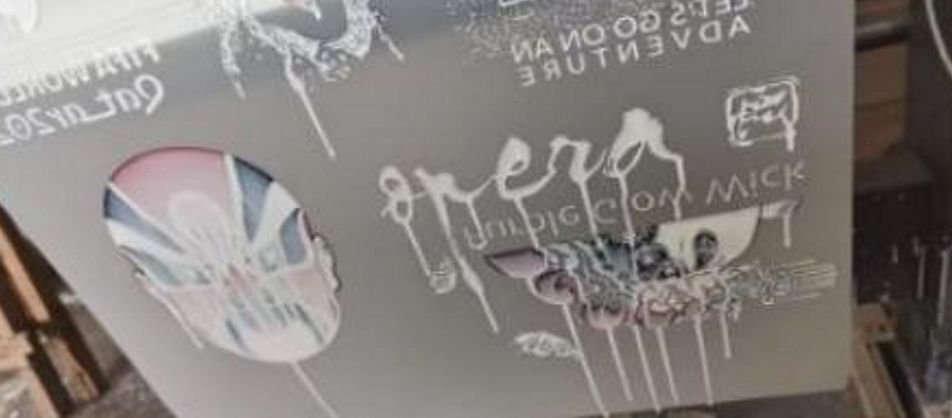

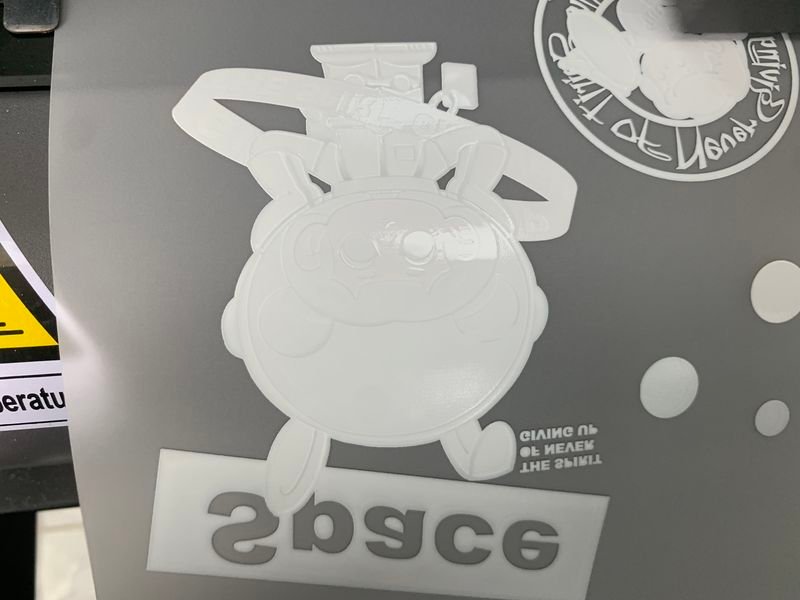

In the following pictures, we can clearly see that the printed white ink cannot stay steadily within a specific range and has a tendency to flow downwards.

Incidentally, problems with the absorbent layer can also lead to “Ink Color Mixing Phenomenon”. See details: What Is Ink Color Mixing Phenomenon On DTF Films?

Leakage Due To Ink or Film Incompatibility

Another major cause of DTF film bleed is incompatibility between printing supplies. Since white ink is used more frequently in DTF printing, some people choose cheaper white ink. And this can lead to incompatibility between different inks.

Coatings on films may also be incompatible with inks, and subtle differences in the level of production by manufacturers may be perceived as a difference between various printing consumables. This difference may be the root cause of white ink runoff.

If colored inks and white inks are not formulated to match, they may react and flow instead of bonding properly. Similarly, if the film coating does not bond both inks, bleed-through is inevitable.

Two Common Causes of DTF Film Ink Bleed

Typically, DTF film bleed can occur when both color ink and white ink bleed or only white ink bleeds. These are two different problems that need to be looked at dialectically.

When Color And White Ink Bleed At The Same Time

This can be the result of poor compatibility between colored and white inks, or they are both incompatible with film coatings at the same time. To verify this, you can simply try it with different inks. We recommend replacing the white ink first and choosing an ink that better matches the current color ink.

When Only White Ink Bleeds Out

When only white ink bleeds out, the direction of our judgment will be simpler. First you need to make sure that white ink has not settled. White ink usually needs to be shaken before use, especially at low concentrations.

Secondly you can look at the amount of ink used for printing, individual designs don’t really need you to print 100% white ink, lowering it by a fraction has the same effect. Both avoid running ink and save on usage. Then there is the check to make sure that all channels in the curve used are turned on.

By the way, it is also possible to have this problem if the output is 100% white ink, see: What is White Ink Buildup on DTF Film

If you don’t see a problem after checking the first two steps, then you need to consider if it’s a film moisture problem. Moisture in the film causes the surface** to absorb a layer of moisture, which takes up the original ink-absorbent coating of the film, causing problems with the surface tension of the film.

How to Prevent DTF Film Ink Bleed

You can try to solve the ink bleed problem in one of these ways:

Selecting High Quality Film

Always choose a DTF film with a good quality ink absorbing coating. If you are not sure whether the quality of the film is good or not, then consider testing it first. Or have the film manufacturer send you a sample. Print test strips with current inks and films before going into full production.

Shake White Ink Well And Maintain Printer

As I mentioned before, white ink settles quickly. If it is not stirred or shaken well before printing, the concentration of the pigment particles can become inconsistent, which indirectly causes bleed-through** of the DTF film. So please make sure to

- Shake the ink bottle before each use.

- Use a printer with a white ink circulation system.

- Avoid clogging the nozzles or opening the passages excessively.

See also: Why DTF Printer not Printing White Ink?

Control Printing Conditions

Improving these following printing steps can also help with ink bleed:

- Reduce the percentage of white ink output through the RIP software.

- Move back a few tens of centimeters based on the current film to see if the film behind it has a similar problem.

- Turn off some of the channel output to prevent too many overlapping paths.

Thoughts on DTF Film Ink Bleed

It is important to note that DTF film bleed is not necessarily a film problem. There are times when a problem with the printer printhead can cause similar problems. Here I’m only judging by the fact that there is a problem with the film, and the specifics depend on your actual application.

The cost of film on the market today is not that great, and there are plenty of opportunities for you to replace the film when you have a problem. If this is what you are looking for, you may want to consider the films offered by Owcors.

FAQs

Q: Is DTF ink bleed always caused by bad film?

A: Not always—but film quality is the most common root cause. Ink quality and printer settings can also contribute.

Q: Can I fix bleeding after printing?

A: Unfortunately, no. Bleeding ruins the print before it’s transferred. Prevention is the only real solution.

Q: Does weather affect DTF Film ink bleed?

A: Yes. Humidity can affect film coating and increase bleeding, especially with poorly stored film.