This guide will help you understand why DTF film matters, what to look for when purchasing it, and how our brand, Owcors, can provide peace of mind with every roll.

Why Is Buying DTF Film So Important?

Every successful DTF print starts with a good-quality film. It serves as the base on which your design is printed before being transferred onto the fabric or object. Without reliable DTF film:

- Your ink may not adhere properly

- Color registration can become inconsistent

- The final transfer may fail, crack, or peel

Choosing the right film is about more than compatibility—it’s about print quality, efficiency, and customer satisfaction.

At the same time, the compatibility between consumables can greatly affect printing. DTF film is important, but other consumables such as ink and powder are equally important.

When the film you buy cannot bring out the effectiveness of other consumables, it can lead to a terrible printing experience.

Six Things to Look for When Buying DTF Film

I’ve talked about how to determine the quality of films when buying them before. See also: How to Determine The Quality of DTF PET Film?

But as these days went by and I got to know them, I think I gained a better understanding. Here are six key perspectives to help you assess the quality of DTF PET film before buying:

Ink Absorption Performance

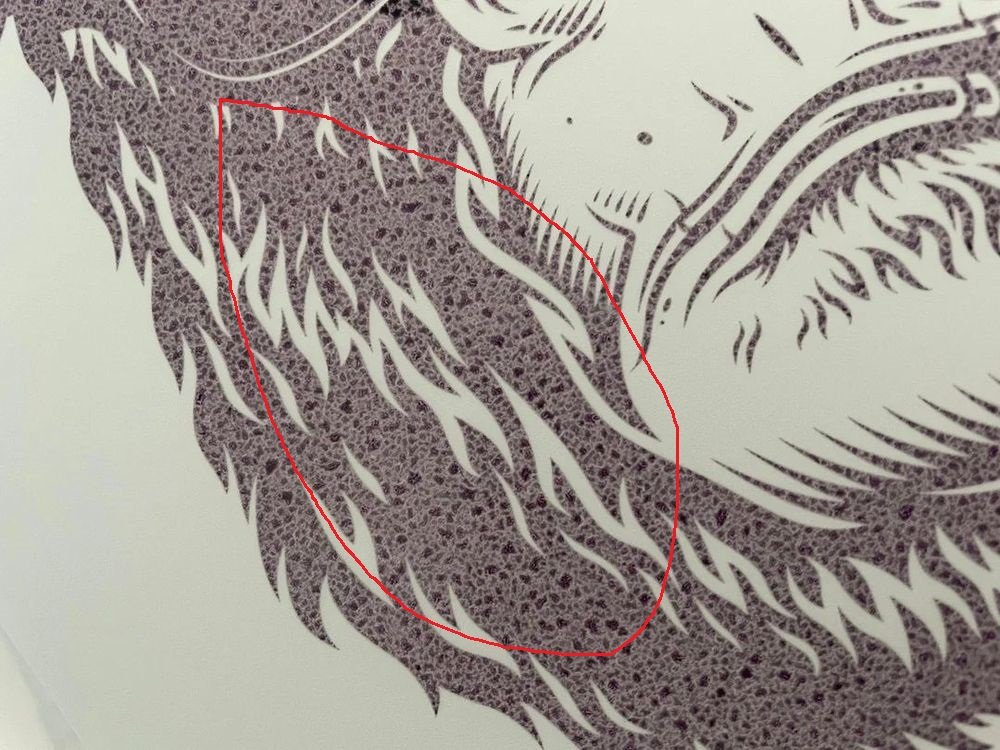

A good DTF film should have excellent ink-receiving capacity. Poor ink absorption can cause blotchy or faded designs, especially where white ink overlaps color. This affects the overall clarity and vibrancy of the final print.

The image below is from a Reddit user’s post. The issue on the left side of the image is due to the film quality; the ink absorption layer is inadequate. If the image to be transferred requires more complex colors, the result would be another story.

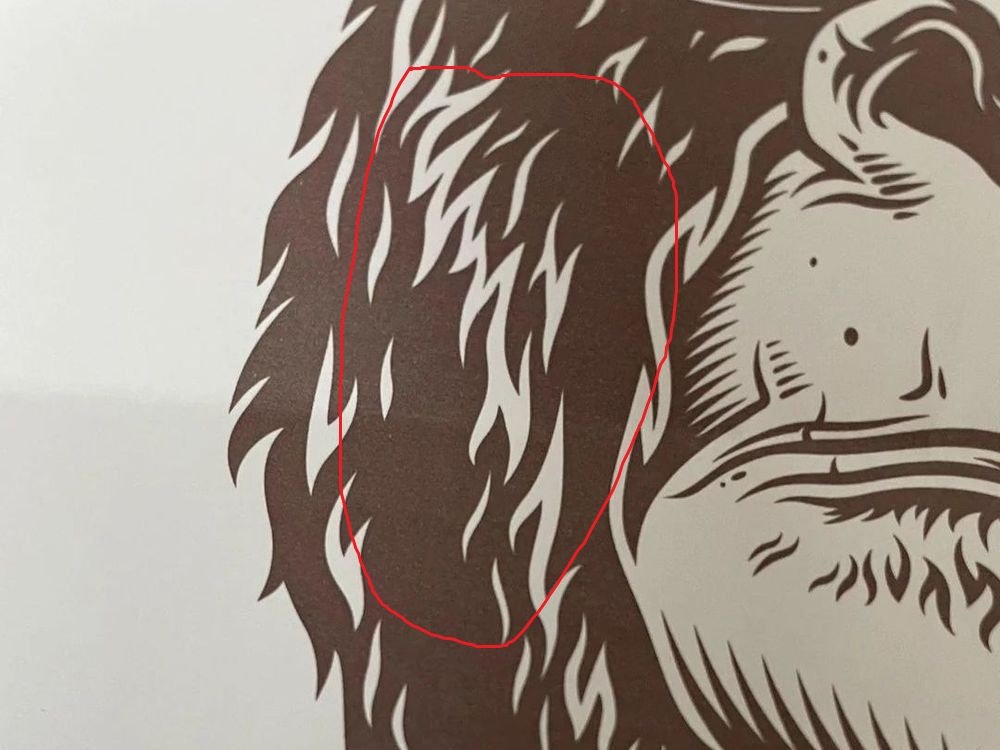

Coating Quality

DTF film features a coated surface layer that holds the ink and adhesive powder. If the coating is inconsistent or contaminated with fine particles, your final image may lose detail or develop random blemishes.

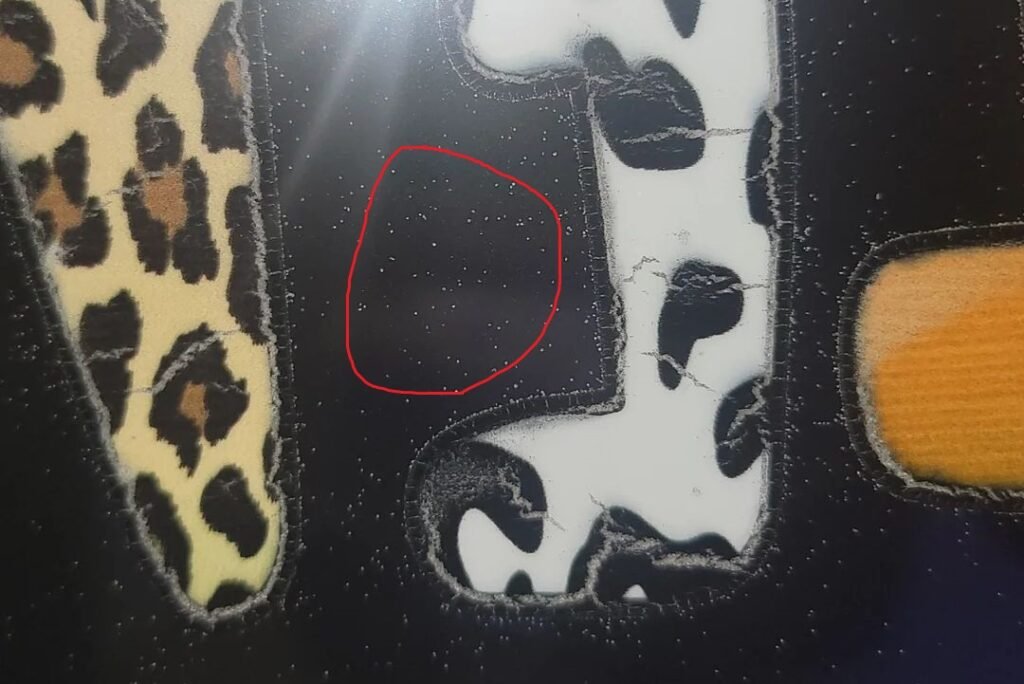

Powder Adsorption and Release

When applying hot melt powder, a high-quality DTF film allows the powder to adhere evenly while releasing excess easily after shaking. Poor films will hold too much residual powder, resulting in patchy or fuzzy transfers.

Ease of Peeling

After heat pressing, your film should peel away cleanly, whether it’s a hot peel or cold peel type. Films that stick too tightly may tear or distort the design, while premium films maintain image integrity during removal.

Surface Oil and Water Resistance

Low-grade PET films may develop oil spots or water marks during printing, often due to subpar raw materials or poor storage. High-quality films resist this issue under normal use and proper storage conditions.

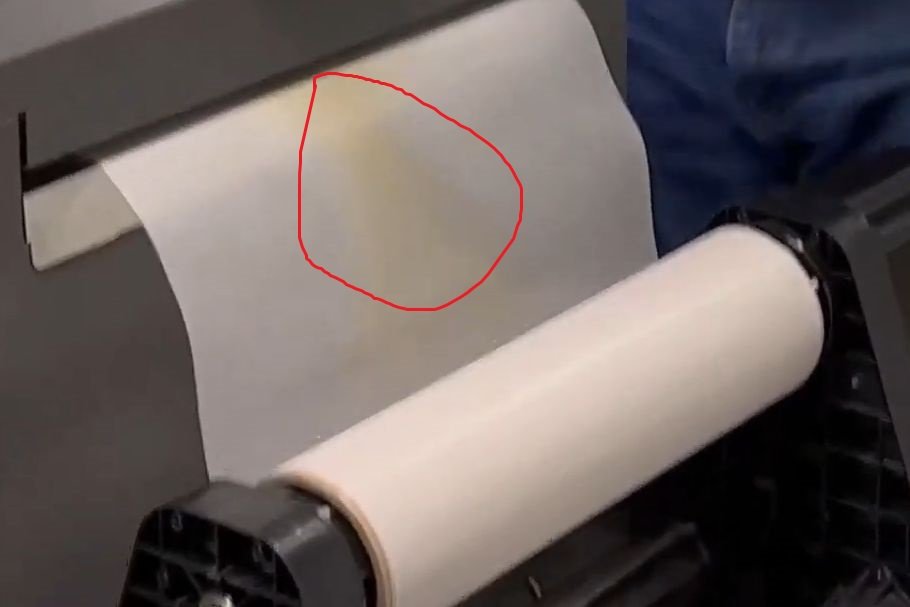

High-Temperature Resistance

DTF transfers require heat curing, and the film must endure temperatures up to 160°C (320°F). If the film yellows, curls, or wrinkles under heat, it’s likely of poor quality. Always choose film that can handle thermal stress without deformation.

Additional Tips When Buying DTF Film

Simply knowing how to judge film quality isn’t enough to master DTF film. You should also consider these practical issues:

- Storage Requirements: DTF films should be stored in a cool, dry place away from direct sunlight and humidity to maintain coating integrity.

- It’s important to prepare a suitable storage environment for your films in advance. Even if you only buy a small amount, you may have some leftover.

- Cutting and Sizing: Make sure the film size (A3, A4, or roll) matches your printer type and production volume.

- Handling: To avoid touching the printing surface directly, it’s best to handle it with gloves, as the oil from your fingertips can reduce adhesion.

- I once saw someone installing DTF roll film with their bare hands. As a result, the coating in some areas of the film was damaged due to excessive force during installation.

- Quantity vs. Usage: Buying in bulk can save money, but only if you can store the film properly and use it within shelf life.

FAQ: What to Know About Buying DTF Film

Q1: Is there a difference between DTF film and regular PET film?

- Yes. DTF film has a special coating that allows ink and powder to bond properly, which regular PET film lacks.

Q2: Should I choose hot peel or cold peel DTF film?

- It depends on your workflow. Hot peel is faster for production; cold peel tends to yield crisper edges.

Q3: How long can I store DTF film before it degrades?

- Typically, up to 12 months if stored in proper conditions—cool, dry, and sealed from dust or moisture.

Q4: Can I use Owcors DTF film with any brand of printer?

- Yes. Our film is tested for broad compatibility across Epson, XP600, i3200, and other common DTF printers.

Q5: How do I avoid powder sticking too much on the film?

- Use high-quality film like Owcors that has proper anti-static treatment, and always shake off excess powder before curing.