What is the wavelength of UV DTF ink?

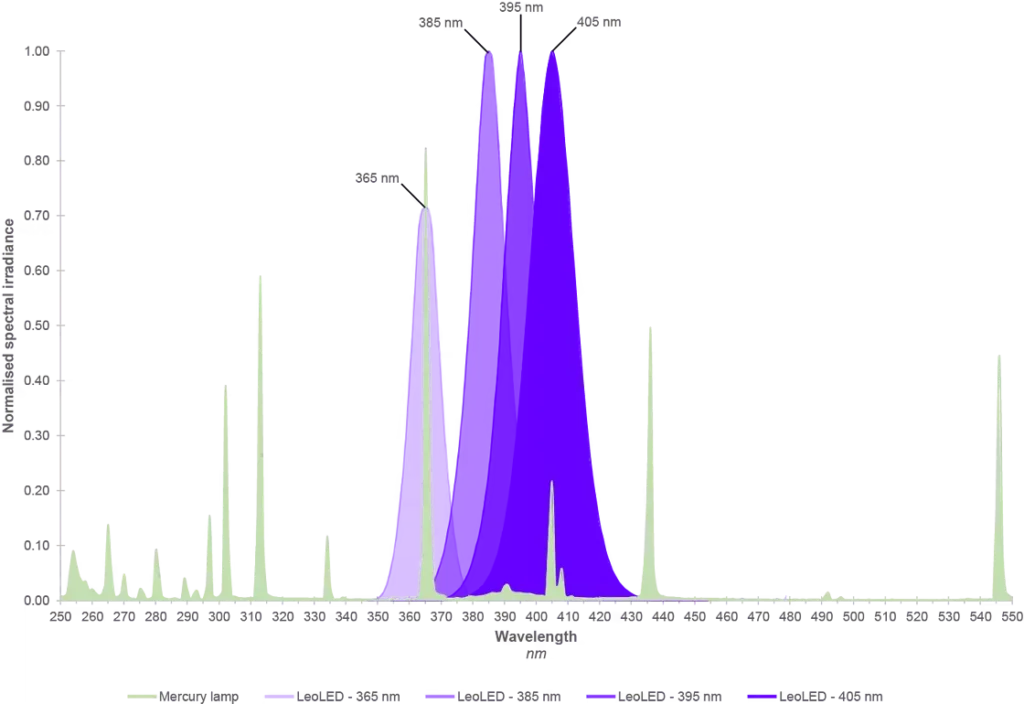

UV inks have a concept of wavelength. When you buy UV ink you need to determine whether the wavelength of the ink matches the wavelength of the UV lamp on the printer equipment. Otherwise, the “photoinitiator” in the ink will not be induced.

UV printers require UV light to cure the ink. If the wavelength of the UV light from the printer equipment is lower than that of the ink, then the ink may not be fully cured.

UV DTF inks are cured by exposure to specific wavelengths of ultraviolet light, usually in the UVA spectrum. The most common wavelengths used to cure these inks are 365 um, 385 um, 395 um and 405 um. The standard wavelength for UV inks in the digital printing industry is 395 um, and inks on the market are generally in the 365-410 um range so some people call it the 395 um upper limit or the 395 um lower limit.

Choosing the right wavelength depends on the ink formulation and substrate materials and other factors. For example, 365 um is usually the most commonly used wavelength, while 385 um and 395 um are often used for inkjet printing.

Here is an article that explains the concept of wavelength in more detail. Click here.

What to do if UV DTF ink won’t dry?

The UV DTF ink is not drying after using the printer, which is a problem you will encounter when printing. You can solve it by the following methods:

- First determine whether the wavelength between the ink and the UV lamp is matched. It should be noted here that the printing equipment UV lamp used for too long will affect the curing efficiency. If your equipment has been used for a long time. It is also necessary to further determine the degree of aging of the UV lamp components.

- Check whether there is a problem with the ink, to confirm whether the ink is shelf-life ink. Whether the opening time is more than 3 months. During this period, you can try to replace a different brand of ink for printing test. To see whether it is because the ink itself caused by the problem can not dry.

- If the above two points after checking are normal, then you can try to adjust the UV lamp position or light-emitting power. UV light is not fully irradiated ink, may not be able to induce the photoinitiator in the ink. Resulting in failure to cure or not dry the phenomenon.

Can UV DTF ink be filtered through a funnel?

Filtering UV ink through a regular funnel is not recommended. The reasons are as follows:

Mismatch between particle size and filter pore size

Ordinary funnels or coarse filters usually have pore sizes much larger than 0.2-0.5 microns. Which cannot effectively intercept potentially large particles or impurities.

Professional filtration requires microporous filters with common pore sizes of 1 micron or 0.5 micron. Sometimes smaller to accommodate high precision printing equipment.

Filtration can damage ink components

Ordinary funnels may carry contaminants such as fibers and dust, instead introducing new impurities.

Improper filtration may destabilize UV inks, such as pigment dispersion or photoinitiator activity.

Specialized equipment is more suitable for filtration

If filtration is really necessary, it is recommended to use industrial grade filters or factory supplied filtration units.

UV ink has been through multiple precision filtration during the manufacturing process. And users may not be able to achieve the same results by filtering on their own.

What if the printhead is clogged with UV DTF ink?

If the aim is to prevent clogging of the printheads, the following measures can be taken:

- Regularly clean the printheads: especially for equipment that has not been used for a long time, to prevent the ink from curing at the printheads.

- Use high-quality UV ink: Choose a regular brand of UV ink to ensure that it has an even particle distribution and low impurity content.

- Installation of filtration devices: Some inkjet printers come with micro-filters in the ink circuit system, which can further protect the printhead.

- Prevent environmental pollution: Keep the ink working area clean to avoid impurities mixed in.

Conclusion

It is important to fully understand the concept of wavelength of UV DTF inks to avoid oops caused by wavelength mismatch when using them.

If the use of ink appears to be undried. You can determine this by checking the ink and the UV lamp.

The particle diameter of UV ink is between 0.2-0.5 microns, and ordinary funnels cannot effectively filter particle impurities.

If it must be filtered, please use a microporous filter (≤ 0.5 micron).

The most important thing is to use high-quality ink and carry out routine maintenance of the equipment to minimize clogging and impurity problems.