Consumables are normally capable of being stored for up to one year, but given the difference between actual and ideal storage, the expected storage period for inks is usually 6 to 12 months, while the expected storage period for films and powders is relatively constant and generally longer than that for inks.

How Improper Storage DTF Supplies Affects Workflow Efficiency

When DTF supplies are not stored correctly, the impact is not only on print quality—but also on production speed, troubleshooting frequency, and even equipment health. Poor storage can turn routine printing tasks into time-consuming problems.

Increased Printer Downtime

Clogged printheads from sedimented ink, film feeding errors from curling, or inconsistent powder melting all lead to stops in the workflow. The more time spent cleaning or adjusting settings, the less time is available for fulfilling orders.

More Frequent Waste and Reprints

When ink fails to adhere, or powder fails to bond, prints must be redone—wasting not only material but also labor. Improper storage of DTF consumables increases the chance of print failures, which can hurt profitability. Can you imagine a scenario where you are in the middle of an urgent order but can’t get it printed?

Degradation of Equipment Over Time

Some consumables can be of poor quality due to storage problems. And using these poor-quality consumables can lead to problems such as surface oils formed when the film becomes brittle mixing with the ink causing it to thicken and clog the printheads. In the long run, internal components may be damaged or require more frequent maintenance, shortening the life of the printer.

FAQ about Storage DTF Supplies

Below I intend to explore the effects of improper storage from each of the three perspectives of ink, film, and powder to give you a deeper understanding of their interactions.

How Improper Storage of DTF Ink Affects Printing

Proper storage of DTF ink is crucial to maintaining its color stability, viscosity, and print reliability. Without correct storage conditions, ink performance can degrade quickly, especially in combination with other poorly stored consumables.

Temperature Fluctuations Reduce Ink Stability

Storing DTF ink outside the recommended range of 15°C to 25°C can cause pigment separation or thickening. If used in this state, it may clog the printhead or produce inconsistent color output on DTF film, especially when the film surface is already compromised.

Exposure to Light Degrades Pigments

Continuous exposure to direct sunlight or high-intensity indoor lighting can cause ink pigments to fade or oxidize. This can result in dull prints, or worse, color mismatches during multi-pass printing, particularly noticeable when printing on moisture-affected film.

Improper Sealing Leads to Contamination

If ink containers are not properly sealed, oxygen exposure can cause pigment degradation or solvent evaporation. This results in visible banding or incomplete ink flow on film—problems that worsen if the film itself has absorbed moisture.

How Improper Storage of DTF Film Compromises Transfer Quality

DTF film must maintain its coating integrity, smoothness, and flexibility for high-quality transfers. Poor storage will directly impact ink adhesion and cause printing or pressing issues.

Humidity Causes Film Expansion or Curling

If stored in overly humid environments, film may absorb moisture and warp. This can lead to feeding issues during printing, ink bleeding, or distortion of the design, especially when paired with poorly stored, overly fluid ink.

Exposure to Dust and Chemicals Damages Film Coating

Dust, oils, or chemical vapors can contaminate the film’s coated surface, causing ink to pool unevenly. This results in blurred images or scattered powder adherence—especially when paired with moisture-damaged DTF powder.

Temperature Stress Makes Film Brittle

Extreme cold or heat can cause the film to become brittle or sticky. This leads to difficulty in feeding the film through the printer or peeling issues during heat transfer. These problems multiply when the ink and powder are also improperly stored, increasing the chance of print failure.

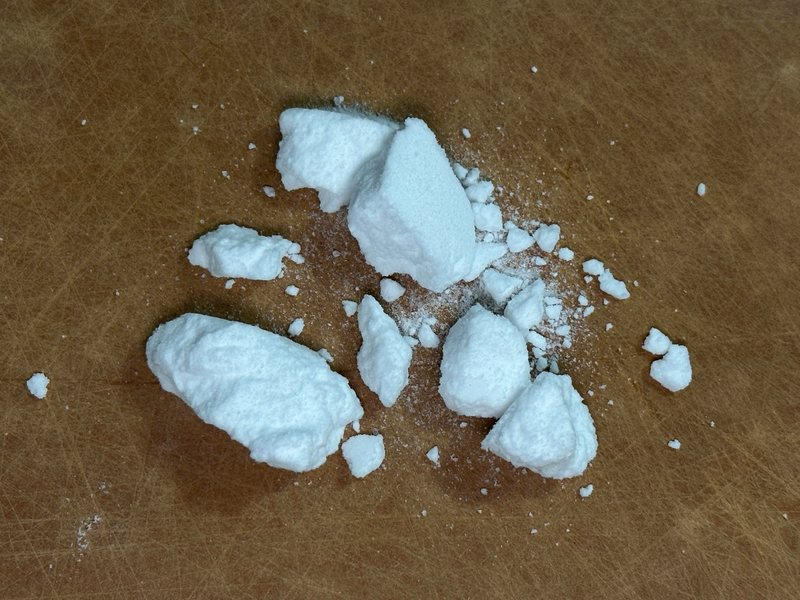

How Improper Storage of DTF Powder Affects Adhesion

DTF powder is highly sensitive to moisture and temperature. Its role in securing the print during transfer makes proper storage a critical factor for ensuring durability and wash resistance.

Moisture Causes Powder Clumping

In high humidity, DTF powder absorbs moisture and clumps. This prevents it from distributing evenly over the ink and may result in patchy adhesion. When combined with faded ink or curled film, the entire print can peel or crack after pressing.

High Temperatures Affect Melting Point

Exposure to heat can alter the powder’s melting characteristics. This leads to poor bonding during the curing stage, especially if the film is brittle or the ink hasn’t properly bonded to the surface.

Contamination Impacts Fusion Quality

Dust, oil, or chemical contamination will change the powder’s ability to melt cleanly and evenly. When applied to prints made with unstable ink or rough film, the final result will often suffer from reduced durability and sharpness.

How Combined Improper Storage DTF Supplies Leads to Systemic Issues

While each consumable plays a specific role, their performance is interdependent. Poor storage of multiple components can result in compounding problems that significantly reduce production efficiency and quality.

Ink and Film Storage Failure Leads to Poor Image Transfer

If the ink is faded and the film is moisture-warped, even the best powder won’t ensure a clean transfer. You may see image misalignment, washed-out colors, or even complete transfer failure.

Powder and Film Degradation Causes Adhesion Loss

When both powder and film are improperly stored, adhesion becomes unpredictable. The powder may not melt evenly, and warped film surfaces may prevent even distribution—leading to incomplete or cracked transfers.

All Three Poorly Stored? Expect Total Print Failure

If ink, film, and powder are all stored incorrectly, the result is not just reduced quality—it’s wasted time, wasted materials, and lost profit. In such cases, printers may face ghosting, color fading, poor wash resistance, and heavy customer complaints. I don’t think you want to accept an order that’s returned by a customer, do you?

Best Practices to Prevent Issues From Storage DTF Supplies

The easiest way to avoid print quality issues and workflow disruptions is to implement proper storage practices for every DTF material. These simple habits can preserve supply quality and reduce costly mistakes.

Organize Inventory By Expiration and Usage Frequency

Label and track your DTF ink, film, and powder using a FIFO (First In, First Out) system. This ensures you always use the freshest supplies and prevents waste from expired products affecting print quality.

Use Climate-Controlled Storage Spaces

A temperature- and humidity-stable room between 15°C to 25°C and 40–60% RH is ideal for all DTF supplies. Keeping your storage environment consistent helps prevent material degradation, especially during seasonal changes.

In DTF supplies, looking at temperature is the best element to prevent problems with storage. As long as you can fix the temperature issues, you basically won’t have too many problems with storage.

Store Supplies in Protective Packaging

Use sealed containers for ink and powder, and keep film in its original dust-free wrapping. This prevents exposure to air, light, moisture, and contaminants—all of which contribute to storage-related print failures.

You can properly purchase some cabinets that are specifically designed for storing items that are easy to manage well while also providing some storage protection.

Conclusion

DTF printing success depends on the consistent quality of your supplies—and that begins with proper storage. From ink viscosity to film flatness and powder adhesion, every element matters. Taking the time to store your DTF supplies correctly isn’t just best practice—it’s essential for delivering vibrant, durable, and professional results every time.