This guide dives into the causes behind DTF white ink shifting and offers actionable solutions to help you correct the problem and maintain consistent output.

Common Equipment-Related Causes of DTF White Ink Shifting

Your printer’s hardware configuration and physical setup play a significant role in ink alignment. If the machine isn’t operating with precise calibration, DTF white ink shifting is almost inevitable.

Misaligned Vertical Calibration

If the vertical (Y-axis) calibration is off, the white and color passes will not print in the same location. This often results in a shadow effect or color misregistration. It’s particularly noticeable on small text or detailed patterns.

Printhead Spray Angle and Nozzle Status

A tilted or clogged printhead can cause ink to spray at an angle, leading to shifted white ink coverage. Uneven ink discharge disrupts the layer alignment and may create double outlines or blurred edges in the final print.

Incorrect Printhead Height

If the printhead is too high above the film surface, the ink may disperse slightly before contact. This results in foggy or expanded print areas, with white ink shifted outside the intended area. Lowering the head too much, on the other hand, risks scratching or head strikes.

There are times when white ink fails to successfully cover colored ink and a similar phenomenon may occur. You can refer to this article at this time: Why Does The DTF White Ink Not Cover The Color Ink?

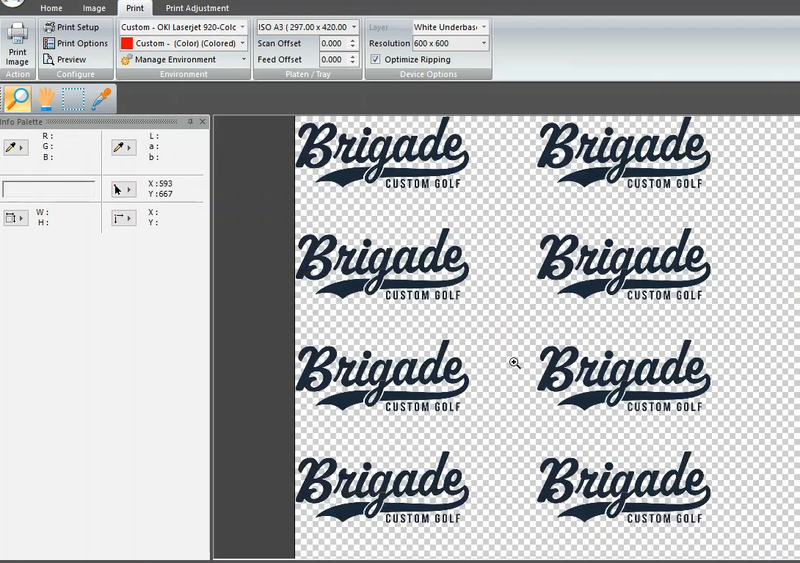

Software and File Issues That Contribute to DTF White Ink Shifting

Your RIP software settings and artwork file quality are just as critical as the hardware. Even small configuration errors can translate to noticeable shifts during printing.

Misalignment in Design Files

Designs that use spot colors or transparency layers without careful preparation may result in mismatched white and color paths. In particular, overlapping layers or missing trapping settings can confuse the RIP engine, causing the white ink to be printed off-center.

Improper Feathering or Precision Settings

Incorrect feathering settings or low step resolution in your RIP software can lead to fuzzy edges and alignment shifts. When these parameters aren’t optimized for your machine and printing substrate type, the white ink often “drifts” around the edges of the graphic.

See also: What is White Ink Buildup on DTF Film

Software Delays Between Ink Layers

If the software or firmware introduces a delay between printing the white and color layers (especially on slower machines), the film may shift slightly or experience drying inconsistencies, leading to misregistration. Usually this is less likely to happen and the equipment has been upgraded now. Just not ruling it out as a factor here.

Offsetting of white ink is particularly noticeable on black fabrics. Often, a second print on black fabric is considered to prove that the offset has been improved. See also: How To Print DTF Ink On Black Shirt

Environmental and Material Factors Behind DTF White Ink Shifting

Even when your printer and software are well-calibrated, environmental and material conditions can still create alignment issues.

Static Electricity Interference

Static build-up on the film surface can repel the fine droplets of white ink, especially in low-humidity environments. This can cause white ink to scatter or cling unevenly—resulting in unpredictable shifting and poor adhesion.

Inconsistent Media Quality

Low-quality DTF films may have inconsistent coatings or surface tension, leading to irregular ink absorption. As a result, the white underbase may expand, shrink, or dry unevenly—misaligning the color layer that follows.

Temperature and Humidity Fluctuations

Large changes in room temperature or humidity can cause DTF films to warp or curl slightly between printing passes, especially on longer runs. This movement—though subtle—can throw off the alignment between white and color ink layers.

See also: Why Are DTF Transfers Cracking

How to Fix DTF White Ink Shifting Effectively

Solving this issue requires a combination of hardware adjustments, software calibration, and environmental control. Taking a systematic approach can help restore precise alignment and consistent results.

Calibrate Printer and Adjust Printhead Height

Run vertical and horizontal alignment tests regularly, especially if you’ve recently changed film or performed maintenance. Set your printhead height to the manufacturer-recommended level, and inspect for clogged or misfiring nozzles.

Optimize Software Settings and Double-Check Artwork Files

Use high-resolution design files and check for correct trapping and overprint settings before sending to print. In your RIP software, fine-tune feathering, ink layering, and step precision settings to eliminate timing or registration delays.

Improve the Printing Environment and Use Reliable Supplies

Maintain a controlled environment with stable temperature and humidity between 40%–60%. Use anti-static film and store consumables properly to prevent surface-related shifts. Investing in higher-quality DTF film can also make a significant difference.

If you are experiencing an inability to print out white ink, check out this article: Why DTF Printer not Printing White Ink?

Conclusion

DTF white ink shifting is a frustrating but fixable issue. By understanding its root causes—whether mechanical, software-based, or environmental—you can take informed steps to prevent it. Proper calibration, quality materials, and a controlled workspace are key to ensuring your white ink stays exactly where it should be: right beneath your design.