Learn About DTF PET Film

DTF PET film is a revolutionary product for the printing industry, changing the challenges faced in mass production of textile prints. When you look at this product, you might mistake it for an “ordinary film”.

In fact, it’s commonly used to transfer graphics on T-shirts to achieve this, which involves a whole range of DTF printing processes. And today we just need to know something about DTF film first.

This PET film is used exclusively for DTF printing and is not used for other printing processes. The film is responsible for transferring the ink and transfer pattern to the substrate in the process, and since DTF means “direct-to-film“, you can see how important the film is in this process.

What Are The Key Features Of DTF PET Film?

Multiple coatings

DTF PET film must have an ink-absorbing layer and a release layer. It must be able to absorb ink as well as transfer the release. There is a difference between this and ordinary films. These two coatings are essential to ensure that the pattern is transferred to the substrate during the heat pressing process.

Heat resistance

PET film has high heat resistance and ordinary films cannot withstand its action during heat press transfer. It does not deform or lose its integrity at high temperatures, thus ensuring the quality of the transfer pattern.

High ink absorption

The ability to absorb ink is fundamental to PET film. Printing ink onto the film without spillage or uneven distribution of the ink is a reflection of the quality of the film. It is also important that the ink dries quickly on the film, the faster the better.

How To Judge The Quality Of DTF PET Film?

Suitable thickness

Thicknesses of films usually range from 75 to 100 microns, and higher thicknesses are not always better. It depends on your production needs and printer. Thick films are generally used for high standard designs, while thin films are commonly used. Higher thicknesses mean higher costs as well, and more consideration should be given to mass production.

Glossy and matte

Matte and Gloss are film surface finishes that have different visual effects after transfer. Matte film transfers and peels better, while glossy film gives a more “shiny” image after transfer. As far as price is concerned, glossy films are usually more expensive.

Coating differences

The two types of coatings that PET film has were mentioned above, the ink absorbing layer and the release layer. There are also differences between the coatings, and not all films are produced in the same way. Generally speaking, the better the quality of the ink absorbing layer, the more pronounced the color saturation after transfer, and there are differences in the release layer in terms of cold tear, hot tear, and sec tear.

A more detailed explanation of the film ink absorbing layer is available here, click here.

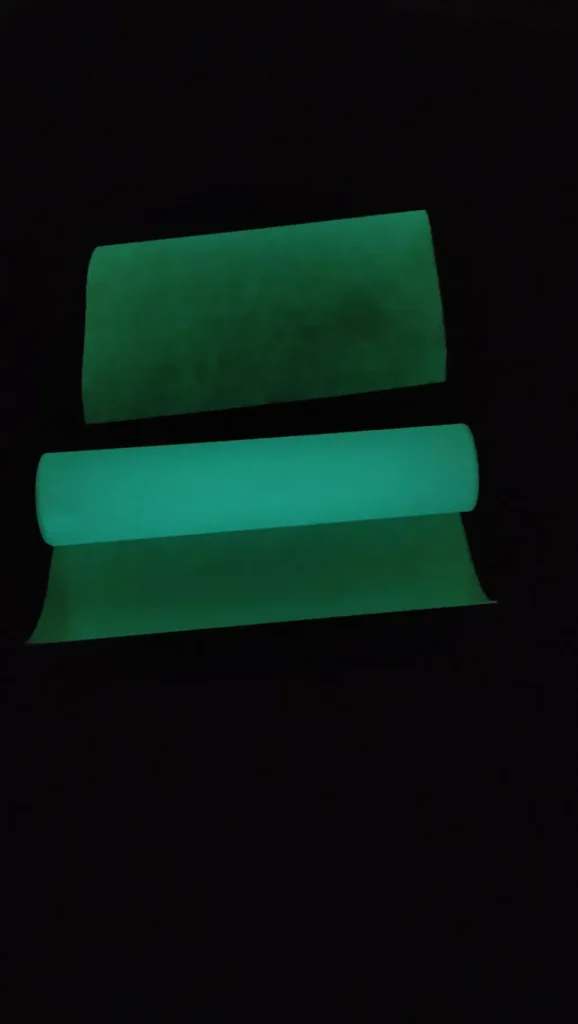

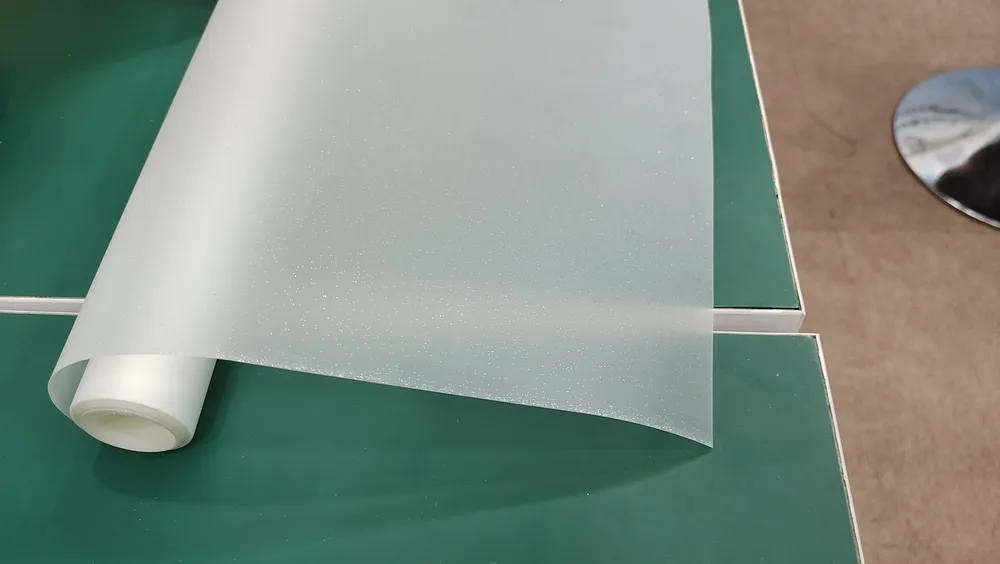

Differences in type

DTF film is not the only type of film, there are also other types of films on the market. Common ones are frosted film, color-changing film, glow-in-the-dark film (green in the dark), and colorful film (colorful accents on the surface of the film).

Common Issues With DTF PET Film And How To Solve Them

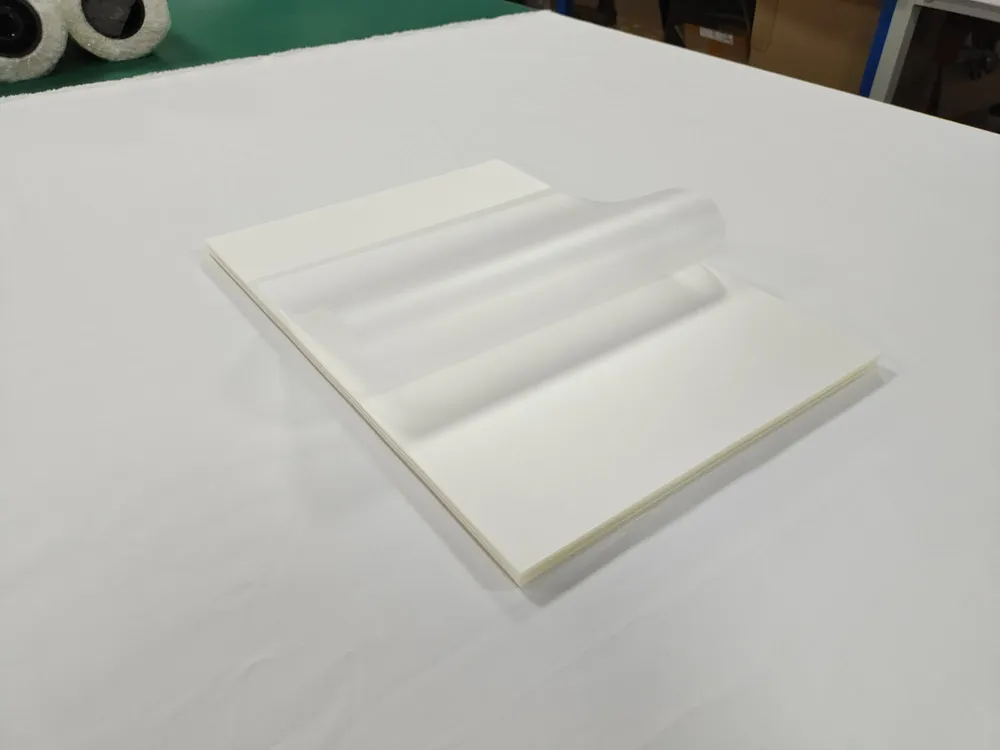

Film curling during printing

Curling is a common problem that can occur when films are exposed to changes in temperature or humidity. Sometimes deformation can also be caused by applying too much external force. To prevent curling, make sure DTF PET film is stored properly and consider printing in a humidity-controlled environment.

Ink smudging on the film

When an image is transferred to a substrate, ink stains appear after the film is peeled off. This indicates that the temperature setting was not correct when the ink was melted by baking with powder or during the hot press transfer process. If the temperature settings are correct, it is time to consider the quality of the film itself.

Maximize The Effectiveness Of DTF PET Film

Optimize heat press settings

Proper heat press settings are essential to ensure the effective transfer of the design from the DTF PET film to the fabric. The correct combination of temperature, pressure, and pressing time should be determined based on the type of fabric and film being used.

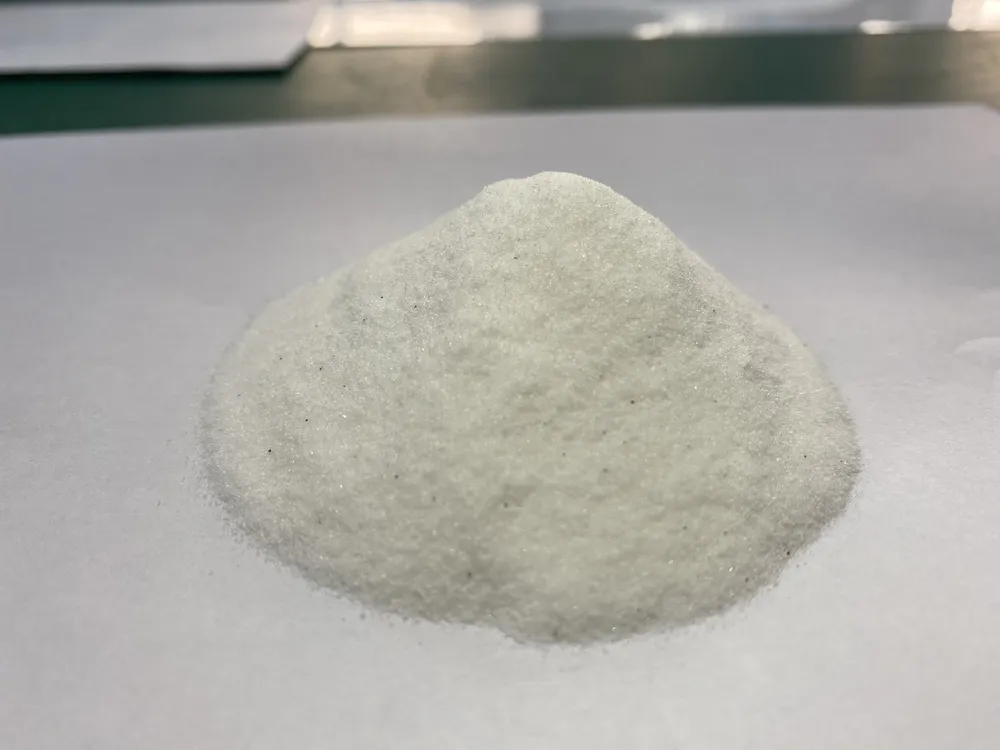

Choose a good powder

PET film also requires the addition of DTF powder before transfer, then baking and melting, so choosing the right powder is critical to transferring the film to the substrate. The right type of powder is matched to the right film to maximize the benefits.

Regular maintenance of equipment

Regular maintenance of your printer, heat press and DTF oven is critical for consistent PET film results. Clean printheads regularly to prevent ink clogging, and make sure the heat press plate is free of debris or impurities to ensure even pressure distribution. Check that the baking temperature of the DTF oven is normal.