In this article I would like to take you through this white ink buildup phenomenon that occurs on the film.

What Does White Ink Buildup on DTF Film Look Like?

it’s not always obvious at first glance. But once you know what to look for, you can’t unsee it.

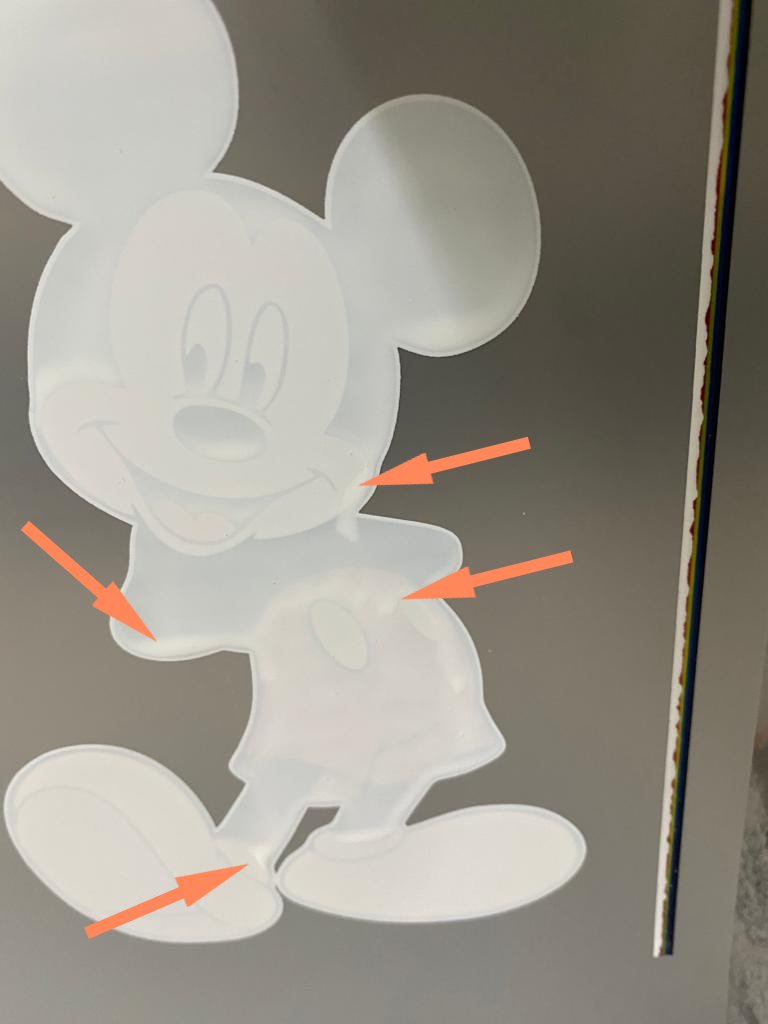

White ink buildup on DTF film usually shows up as:

- Layered ink smears under your color prints

- The white ink collects at the bottom of the print area, where it appears to stand out more

- In severe cases, color ink appears to float or shift, because the white layer underneath isn’t stable

It’s not always the ink or the printer that causes these problems, it could also be the film. Film acts as a necessary thing in DTF printing. Problems with it can affect the print or it can affect the transfer.

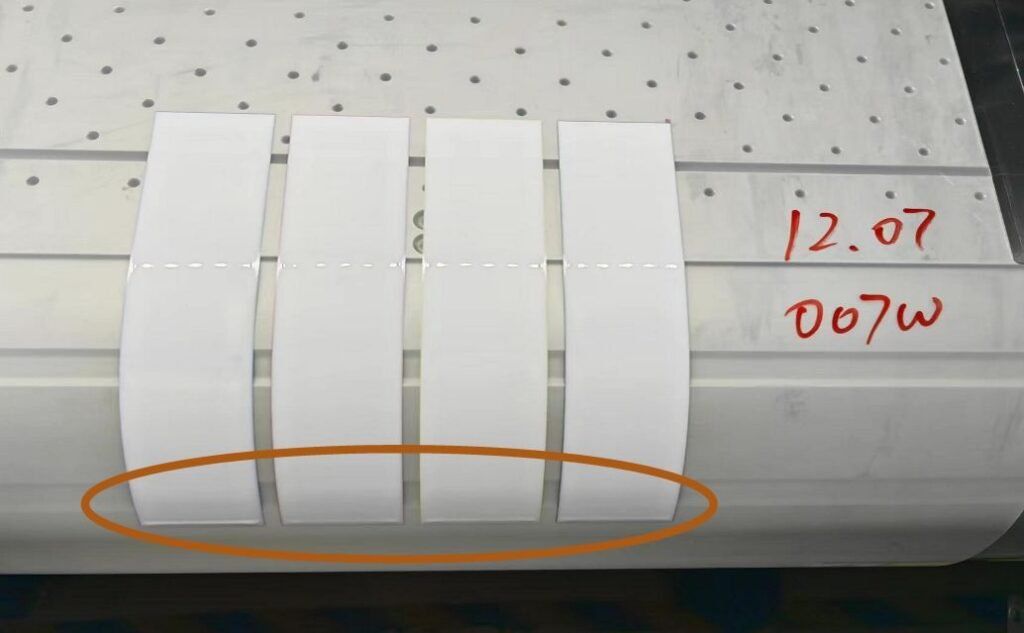

The picture below demonstrates the white ink buildup, which is relatively unobtrusive. You just focus on the raised white ink at the very bottom of the print layer.

Why Does White Ink Buildup Happen on DTF Film?

White ink buildup on DTF film happens when the balance between ink, media, and environment gets thrown off. Here’s what’s usually to blame:

- White ink sedimentation – This one’s a classic. White ink is thick, and if it’s not agitated often, the pigment sinks.

- Overloaded underbase settings – CMYK + 100% white sounds great for coverage, but too much white can’t dry evenly.

- Excessive nozzle output – A similar situation occurs if your RIP settings leave all white ink channels wide open.

- Moisture in the film – Humid conditions or improperly stored films absorb moisture, causing the ink to pool instead of bond.

Another thing to understand is that white ink buildup is essentially a reaction of the same nature as film oiling.

Simple Fixes for White Ink Buildup on DTF Film

Fortunately, dealing with white ink buildup on DTF film doesn’t require you to go to great lengths. In most cases, small adjustments can make a big difference.

Here’s what to try:

- Agitate white ink – Especially for budget or eco inks, sedimentation is a constant. When you use it, prioritize stirring before you go ahead and use it.

- Reduce the white layer density – lower your RIP curve slightly or deactivate some white ink channels.

- Store your films properly – sealed, flat, and in a dry, cool place. See also: DTF Films Storage Guide

- Print in shorter batches – that way, you can course-correct early instead of wasting meters.

Usually after adjusting in these ways, the white ink buildup will be reduced. If you find that none of these ways have allowed you to improve the problem, then it’s possible that other parts of the process are at fault. Like the ink or the printer.

You may also want to consider replacing the DTF film, there is usually a compatibility difference between DTF films made by different manufacturers and different inks. Maybe you don’t have these problems when you change the film.

What Happens If You Ignore White Ink Buildup on DTF Film?

Ignoring white ink buildup on DTF films usually results in these conditions.

- Affects baking and curing: Once the powder is added to the baking, too much white ink buildup will cause some of the powder to fail to finish curing, affecting the final transfer.

- Reduce the printing quality: similar to the text blur, gradient stripes, wet edges and other phenomena.

- Transfer cracking: some patterns appear cracked, and the traces become more obvious after one or two washes.

The transfer cracking that many people experience may stem from this phenomenon. See also: Why Are DTF Transfers Cracking

Conclusion

White buildup on DTF film is a phenomenon in which white ink collects underneath the printed surface. It is usually related to the quality of the film. You can fix it by agitating the white ink, reducing the amount of white ink, or replacing the film.